NANO INSTALL

When I began this project, I only had access to an ESU Micro v5. But since I had made all these changes, I bought a v5 Nano with what appears to be called the revised v2 board. This board makes the whole decoder thinner and shorter than the v1 with the NEXT 18 connector (you can tell the difference because the NEXT 18 board is small, but the V2 board runs the length of the decoder).

This was a great decision because the Nano is not a whole lot smaller than the Micro, but in THIS application, those millimeters make ALL the difference.

The Nano fit wonderfully and is currently the decoder of choice for me in this model. In fact, it almost fits entirely inside the firebox. (I’m counting on ESU to one day make one that WILL fit!).

The first step was to remove unwanted function wires. The Nano V5 v2 comes with a LOT.

I removed the purple, pink, green and mint-green wires.

I made a few other changes.

The yellow wire going to the tender was rather stiff- so I replaced it with a thinner wire (very thin excess wire from the LEDs). I used black for negative.

I also needed another tap on the blue positive wire so I installed a thin wire (red for positive). I'll paint it black later.

I bundled these with the speaker wires.

I then made a wiring harness with TCS micro-plugs.

6 prong plug goes to the board on top of the motor: red, black, orange, gray, blue, white.

The other bundle to the tender received a TCS 4 pin microplug.

Since the loco was all disassembled, I did more prep work on it to make life easier and safer for the expensive decoder.

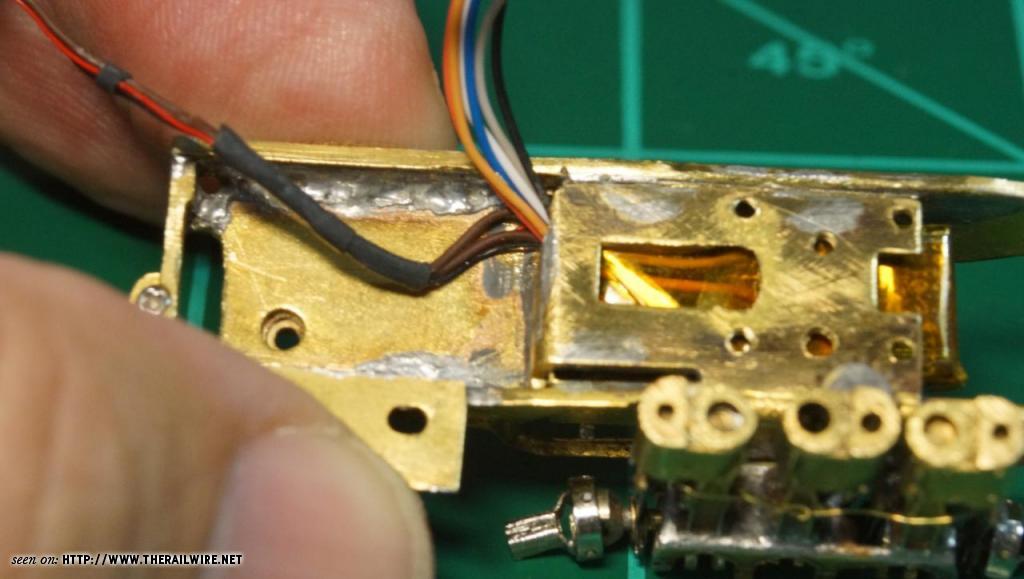

I opened up the rear end so the plug to the tender could fit.

I also opened up the main hole (rightward in this photo) in the frame for the 6-pin bundle.

Lastly, I opened up the edge where the wires slide down in order to minimize the risk of sharp metal cutting the wire sheathing as it slides.

Here is the tender bundle moving through.

Now the 6 pin bundle makes it way through. (opposite view)

All the wires through the larger hole.

Top view. Notice the Nano is shorter than a V5 Micro.

Even though the Nano is shorter, there is still a risk the boiler shell will hit the decoder-- so I trimmed the boiler back a bit at the bottom.

Now the shell actually fits much better. I had not realized the previous V5 Micro was causing a small obstruction.

I made one last change as a safety improvement.

With all of the wires coming up the side of the motor, there is a slight risk of the shell pinching a wire.

I took a Atlas or Kato pick-up strip and trimmed a piece, drilling a hole for the motor screw.

I then installed the harness protector which runs down the side of the motor.

Here is a high view.

Time for a test run.

WOW! The sound is so much improved by getting the speaker away from the motor and crowded cab and moving it to the tender.

The volume is much louder. I am very pleased.

In the future, I may add the keep alive module. It will sit in the side of the cab where the speaker was formerly. I’m not using one now. More on that later.

So here is the brass Shay family to date- they are all different.

And one more is now on the way! (thanks again Chris!)