EDIT: if you are new to this thread and don't want to wade through almost 50 pages, go to page 36 to see some models.

Pages 1-20 are a lot of discussion and development.

About page 20 is building.

This thread is dedicated to pooling ideas to make a pretty cool locomotive.

The TP56 is a switcher locomotive engine and body mounted directly onto an SD40-2 truck.

made by a company in Canada.

This just begs to be modelled.

The perfect starting truck appears to be the truck from a Kato SD40-2 mid version

Not the Snoot and not the early version.

The mid version has the worm built into the truck and has a finer worm to make it slower.

editedYou can see the part number on the truck. Currently comes in:

black- Kato part # 929341

silver- Kato part # 929343

and BNSF green- Kato part # 929347

I think a good possible chassis in the Kato B unit driving chassis.

11-105, 106 or 107. (the only difference is the sideframes- which we don't care about).

There may be something better out there. But this is what I'm going to try first.

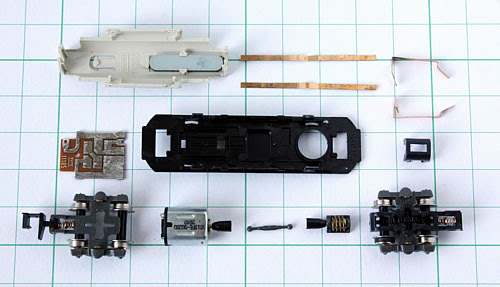

Here is the chassis disassembled. (photo borrowed from the net)

What makes this a good choice, I think, is the size of the motor. Admittedly fast, but the size is great.

Also, look at the u-joint shaft and worm u-joint cup.

Shazzam! They are identical to the parts in the SD40-2 truck.

In this shot....

Right- SD40-2 shaft

Middle- B unit chassis shaft

Left- B unit cup

So here is a side-on shot of the Kato HT-C truck.

Now, we have two possibilities for mounting this motor. I'm cutting and pasting trying to keep everything to scale (what I call, virtual kitbashing).

First, lets try putting the motor in the front.

This way has the worm placed directly on the motor. The motor shaft MIGHT be too short. And some material from the worm cover might need to be removed to get the motor close.

As you can see it sticks out a little too much.

And here is a shot of the Kato worm cover removed. The front of the truck is to the left in this shot.

Here is the front of the truck. This might not work because maybe you can't remove material from the cover because that spot holds the worm bearing.

So let's try the other end. This is my first choice. Room seems to be better.

Disadvantage is that we have to couple the shafts somehow.

One possibility might be to trim the Kato SD40-2 cup and use it like a joiner to join the shafts.

Another possibility might be to cut and splice the B unit grey shaft and make it VERY short.

If that works, a Shapeways part might work.

Another possibility would be to use some K&S brass tubing as a kind of u-joint. This small tubing just presses into the cup.

Which way will work?

Won't know till I get a chance to try it.

But this should start us up with possibilities.