My questions are never easy ones.

So... I have created all new tender trucks for my 0-6-0 project. I have made my own wheelsets, sideframes, the whole darn thing.

It looks nice and it runs...

almostThe problem:

I am having some intermittent conductivity/stalling issues. And I should point out that I had these same issues

even when I used Kato Mikado trucks under the tender. That's important, because it strongly makes me believe that

my problem has nothing to do with my new trucks. It is something fundamental I don't understand about wheels,

metal, and pickup.

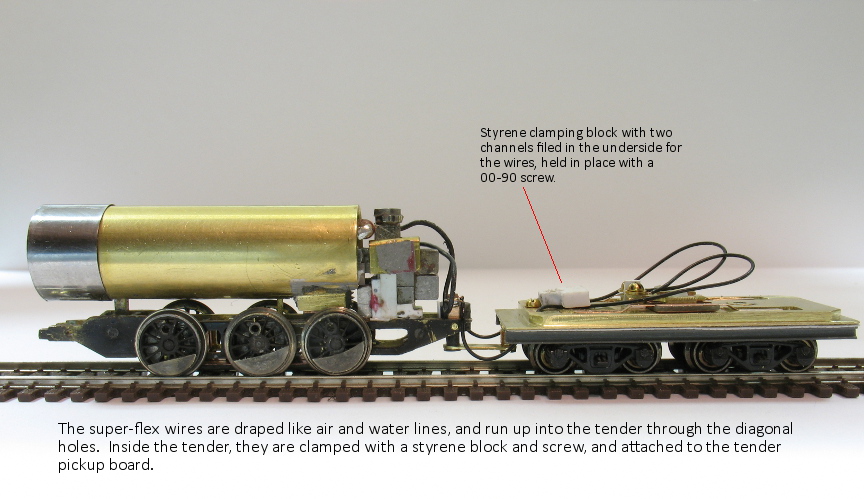

Recall that the tender pickup/truck system looks like this:

So, with rails perfectly clean, freshly wiped with alcohol, wheels freshly cleaned the same way,

it runs beautifully, down to a certain point. But if I make it creep along at, say, 3 mph, every once in a while, it will

stall.

Important facts:

1. When it stalls, current draw is zero, so it is lost pickup, not a mechanical bind.

2. It does not always happen at the same place on the track

3. When it stalls, I can take a whisker of fine wire, jumpered to the rails, and touch a wheel on the tender, and it will

start up, meaning that that wheel had lost contact on that rail.

The whisker is important, because it allows me to touch the wheel

without mechanically moving the engine or wheel.

3a. To double-confirm this, I tried touching the wheel with the whisker over and over WITHOUT the other end of

the whisker being connected to the rails, and the engine does not start up again. So I am definitely not nudging anything to cause it to get going. And as soon as I connect the whisker to the rail and touch the wheel, it runs.

4. I tested this many times, touching the wire to a different wheel every time. It makes no difference which wheel I choose.

It always starts up.

This means, to me anyway, that the lost contact cannot possibly be in the axle points, cones, the "thumbs" that go up into the tender or the tender floor strips or anywhere else. If hot-wiring to a wheel makes it go, that means that the wheel

has lost contact with the rail. And in fact, since I tried this over and over with different wheels, it means that ALL FOUR wheels on one side have lost contact with the rail.

===============================================

Whew.

Now to my confusion.

How on earth is this possible?

4 nickel-silver wheels on nickel-silver rail, all clean, with a good amount of tungsten weight on top of them, and they are all not conducting? I could easily see it if there were only 2 wheels, but 4?

Oh.. and I should point out that all the wheels on this thing consistently roll beautifully. I don't have any dragging or wheels that don't touch or won't roll. I stackied an extra 20g of weight on top of the tender just to see if that would make

any difference. Nope. The problem doesn't change at all.

This engine is powered by a 3v motor that is zener limited, so the voltage from track to wheels during these tests

is about 7.5 volts. In other words, I am not trying to power this engine on the hairy edge with only

1 volt on the rails.

What do I not understand about conductivity between a wheel and a rail?