These cars were inspired by different ones I've looked at but none are true copies of any that I've seen.

On the 'low bunk' car shown above chains would probably be used to hold the logs on the car. More info, images and print file links for this car

( HERE ).

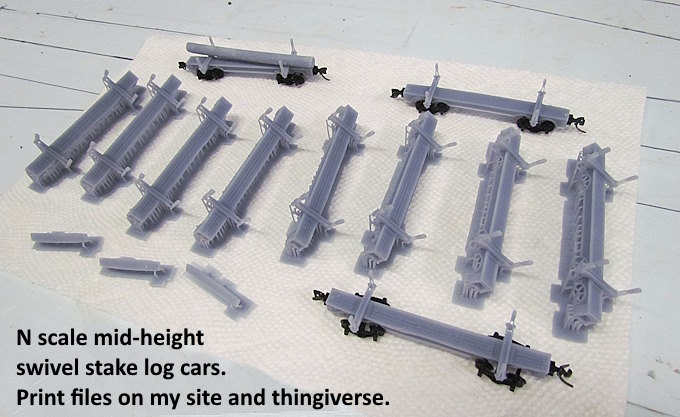

The car above I call the 'mid-height swivel stake car'. I've see a couple of these and believe they had pins at the bottom of the stakes that could be pulled allowing the stake on that side of the care to swivel down and the logs could then roll off the car into a mill pond.

More info, images and print file links for this car

( HERE ).

The last car has 'fixed high stakes'. The logs would be picked off the care one or more at a time or a huge forklift like a

Wagner logstacker could be used to lift the whole load off at once.

More info, images and print file links for this car

( HERE ).

---------------------------------------------------------------------------------------------

Coupler and Truck Installation:

I haven't had to do much cleanup on these prints after the supports have been removed and that takes less than 5 minutes.

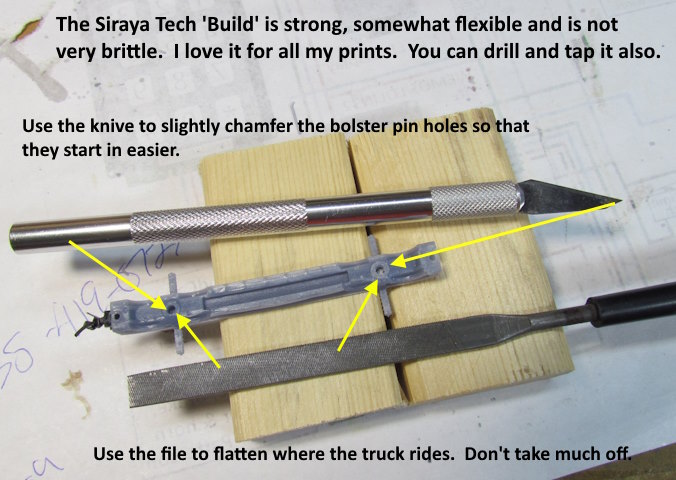

You want to flatten out where the trucks sit under the car. Don't get carried away, just a little file work will flatten them. Also take a knife and run it around the holes that bolster pins go in. Chamfer the top of the holes just a bit helps when you push the pins in.

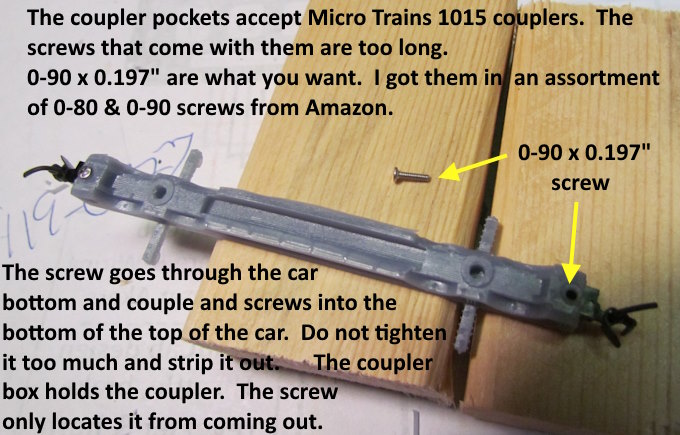

The screws that come with the Micro Train 1015 couplers are too long and will go through the bottom of the top of the car and stick out. You want to use 0-90 x 0.197 length screws for this. I got an assortment of 0-80 & 0-90 on Amazon and I think also eBay at one point.

With my printer I haven't had to clean the inside of the coupler box up much on most prints. The coupler slides in and is snug in the box.

If the coupler won't go into the coupler pocket chamfer the entrance a little with a knife and clean up any print problems/trash from inside the pocket. If you still have a problem getting the coupler in file the sides of the couple box and round the corners. It should start in now with possible a little push needed.

The hole in the bottom of the coupler pocket is large enough the screw will slide through it and also the coupler. Then screw it gently into the top of the car body. Don't force and strip the threads the screw is creating out. The screw doesn't have to hold the couple up like in some cases as the pocket does that. The screw only prevents the couple from sliding out. Snug is good enough on the screw tension.

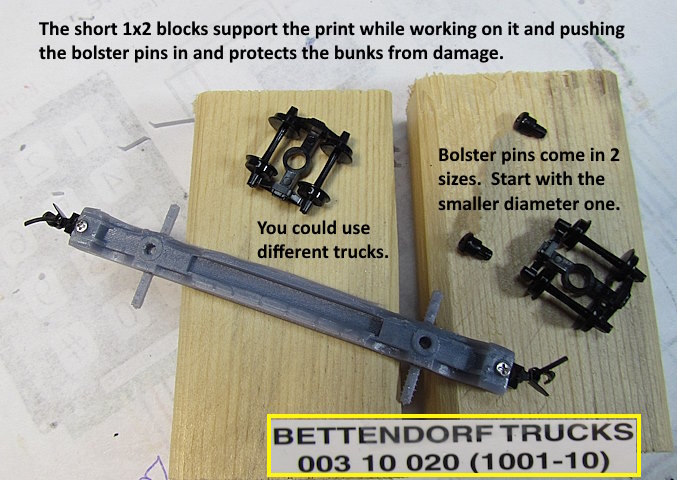

If you don't use something like the blocks shown above to support the car while working on it the tops of the bunks on the ends will probably be damaged. The support also helps while you are putting the coupler screws in and the bolster pins. Put the bunk in the space between the two blocks.

I chose Micro Trains Bettendorf trucks. They come with two bolster pin diameters. Start with the smaller one. After running the knife blade around the hole I've had no problem using the smaller pins that come with the trucks. With the blocks supporting the car you can use some pressure pressing the pins in (at least with the 'Build' resin).

I feel I have the car/coupler height 'close enough'. With the box there is no way to change that.

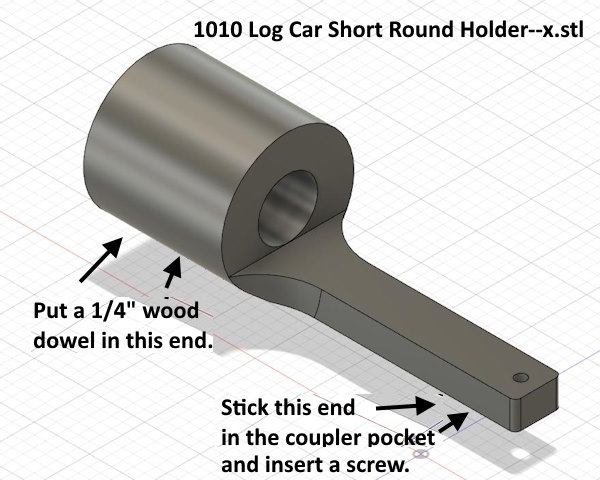

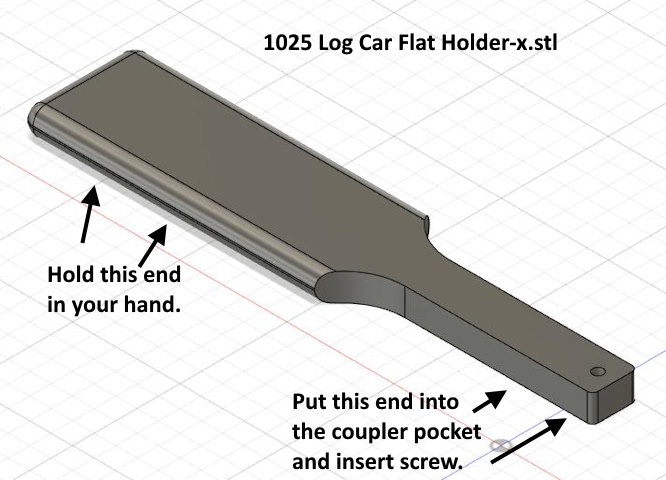

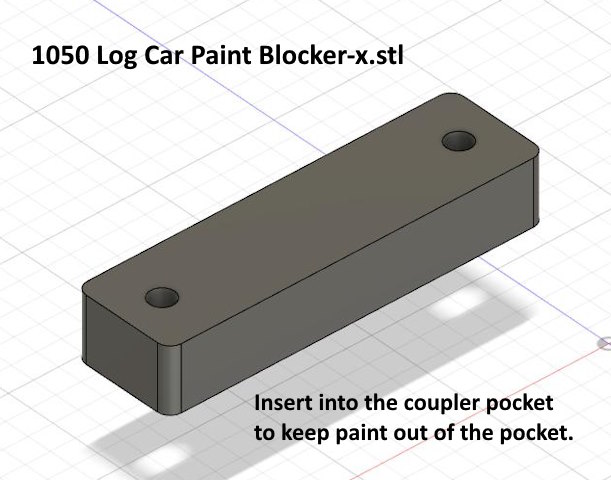

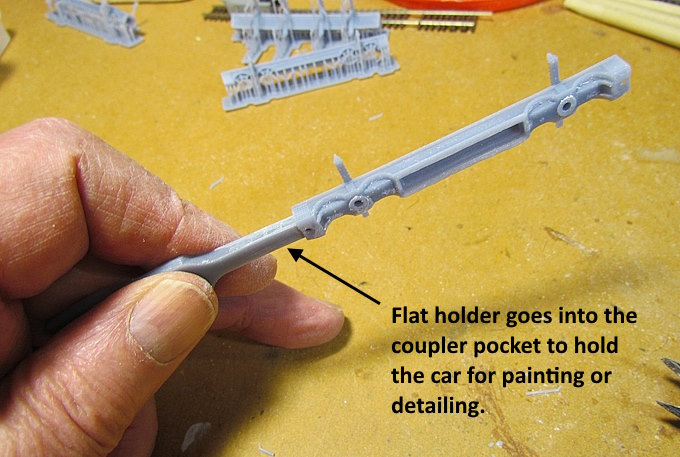

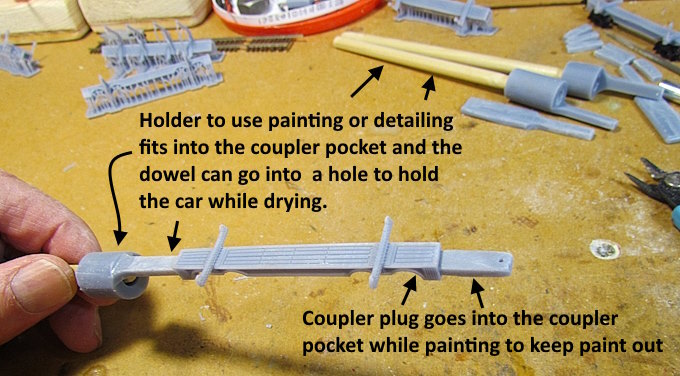

One can print the following tools to help hold the car while painting and/or detailing.

The right end of the tool above goes into the coupler pocket and you can run a temporary screw up through the coupler pocket and tool to keep it in the pocket. You can put a 1/4” wood dowel in the other end to use as a handle and after painting you could put the dowel into a block with holes in it and leave the car there until the paint dries.

The tool above is similar t the one before it but doesn't use the wood dowel. The flat end of the tool can be used for a hand grip.

The last tool above is a simple plug that can be inserted into the coupler pocket to keep paint out of the pocket while painting.

The tools are all close to the right size on the coupler pocket end but use a file to get them where they are a good fit for you. Also take a knife blade and run it around the inside lip of the coupler box to remove any flashing that might be there.

.

You will be able to find the print files for the tools with the print files for each car.

=============================================================

A link to this whole build

( HERE ).

Sumner