When I see with a dial indicator that there is .060 side movement and there is only oneplace that a wheel gauge will fit there is some thing WRONG! I removed the drive axle with wheels and rolled them across a flat surface,

The drivers should maintain at 90 degrees to the flat surface- not so, you could see with your eye there was a real bad problem.

Believe me I looked at all ways to correct before the press came out.

Sat on the work table for several days at a time before trying some thing else only to come back to the same conclusion.

Jerry,

This helps a lot. You didn't explain that you did this in your original diagnosis.

Boring out the driver hole a little, and then setting the axle in there with epoxy is a good idea. With only .001" bore-out, you won't really have to worry about the driver ending up "off center" on the axle. A .001" error is so small that it won't matter. Heck, the commercial drivers probably aren't concentric on the axles to within .001" anyway.

A jig to set them square while the epoxy dries - yes, I've done this exact thing with my home-made drivers.

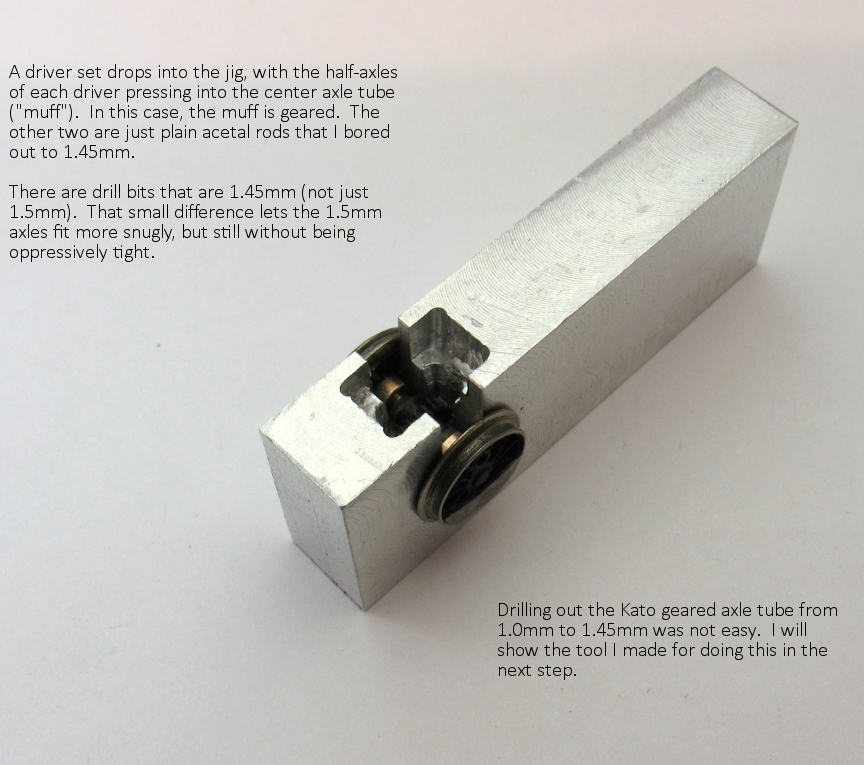

It looks like this:

(just a block machined to the correct width, with a space for the axle gear to go)

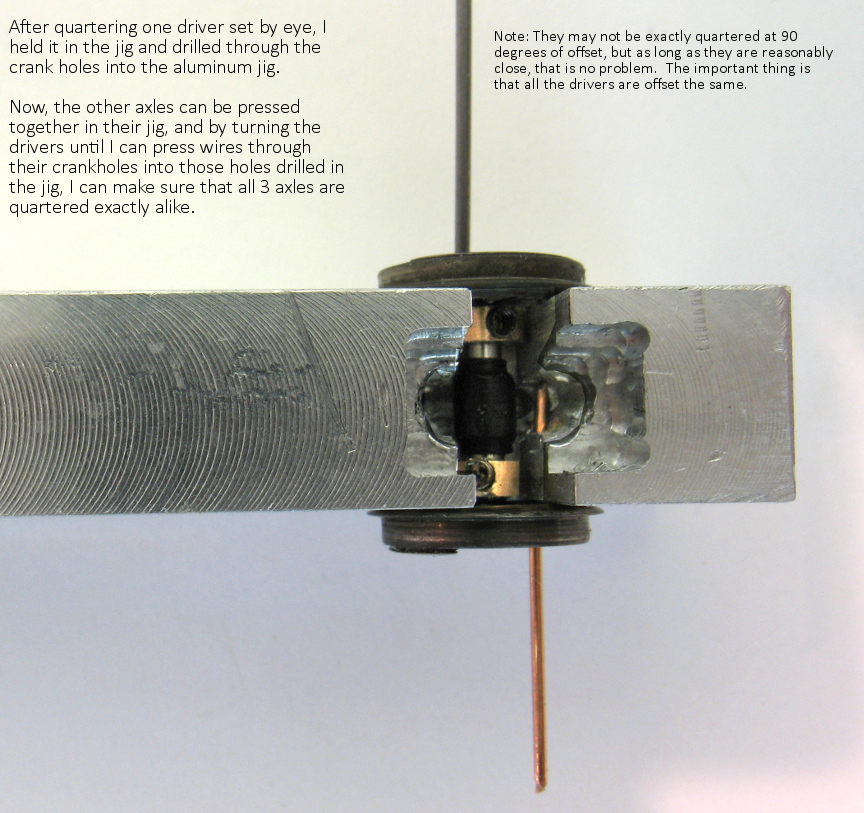

And you can drill two holes in either side of the block to set the quartering. You can drop one of the other wheelsets in the jig, and just drill through their crankpin holes with a pin vise to get the holes in the jig at the correct place so that your new driver will match.