A while back I noticed that one of my Briggs Models 8-44CM resin shells was warped. Notice the one on the left is leaning to the left.

I posted this photo on the Weekend Update and received several helpful suggestions, all including the use of heat to set it right. I had used hot water to straighten flat styrene and resin parts prior to assembly but never on an assembled painted model. Embracing the, "What's the worst that can happen", mentality I figured I'd give it a shot.

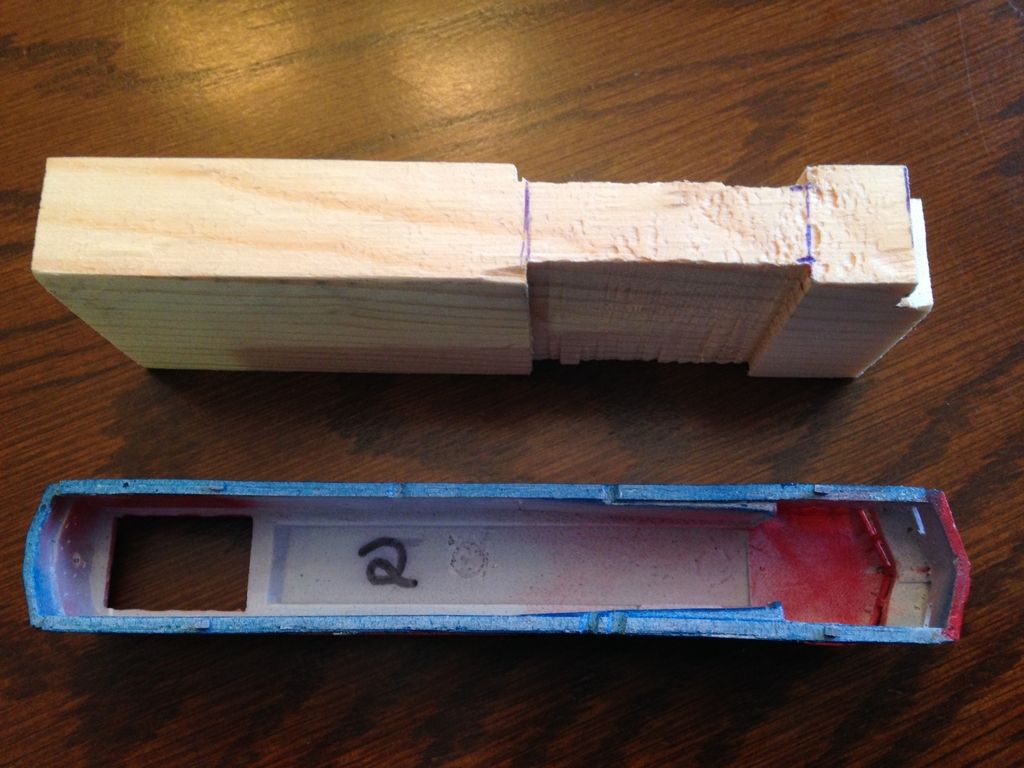

Thankfully I had a second shell that was straight. I measured various points inside the shell and came up with a width. I then cut a 2x4 block out on the table saw and sanded it so that it fit snugly but didn't require force to fit it inside the shell. I also cut relief for the cab and where the tapers behind the cab are.

I boiled up some water and held the block with my tongs. I submerged it in the water for 10 seconds. It relaxed and almost fell off the block when I removed it, which would have been catastrophic, so in the future I'll set it up so I can submerge it right side up.

I let it sit after draining until it was no longer hot to the touch and slid the shell off the block. The resin was still soft enough to position parts with a light touch so I fixed slight bows on either side, over the taper I had cut out, and that left me with a perfectly straight shell.

Quite an improvement:

The whole process took about 20 minutes.

Hopefully this can help someone in the future.

Craig

Edit: while I'm on the topic, here a some parts I straightened a while back. These are frame pieces for the Briggs Models M420. They were wavy like crinkle cut french fries. I lashed them to flat sided pencils with dental floss and submerged in hot water. Worked like a charm, except in the future I will use un-waxed dental floss. Ugh.