I recently did some repairs on someone's Bachmann EM-1. The two issues involved are not specific to the EM-1, so I thought I would share a few photos on the repair as they may be handy to others.

Issue 1: Engine stopped dead while running. Would then run very slowly, but the front engine truck wasn't turning, just dragging.

Issue 2: Spotty pickup (stalling issues) - broken wire to the front engine truck.

Issue 1:

The front engine truck was jamming because the crank screw on the eccentric crank was loose, letting the eccentric spin around

eventually to a bad spot and jam. Checking the engine, I found that all 4 crank screws were loose. I positioned the cranks

correctly, tightened them all, and then found that the engine had a bad lope/tight spot in its rotation.

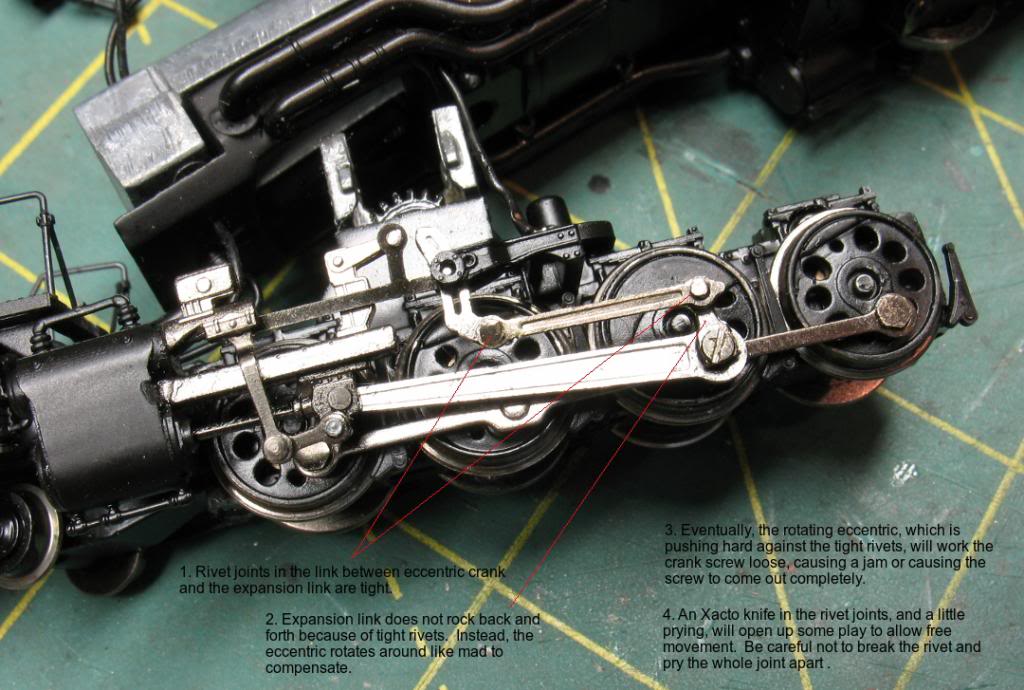

Eventually, I found that the bind was in the link between the eccentric crank and the expansion link.

Here's a photo that explains it all:

Remember, if you don't see that expansion link rocking back and forth like it should, and instead the eccentric is just

whizzing round and round, something is wrong.

Issue 2:

One of the 2 wires from the front engine truck was broken off, so there was no pickup from one rail from the front truck.

This pickup scheme, of having bronze tangs mounted in the truck, with wires soldered to them and snaked up into the frame,

is also used on the Bachmann 2-6-6-2. It's a crummy design, period. The potential for the wire to break off is high,

and the wire itself interferes with the free swiveling and rocking of the truck. It can be made to work if you get the wire

positioned "just so".

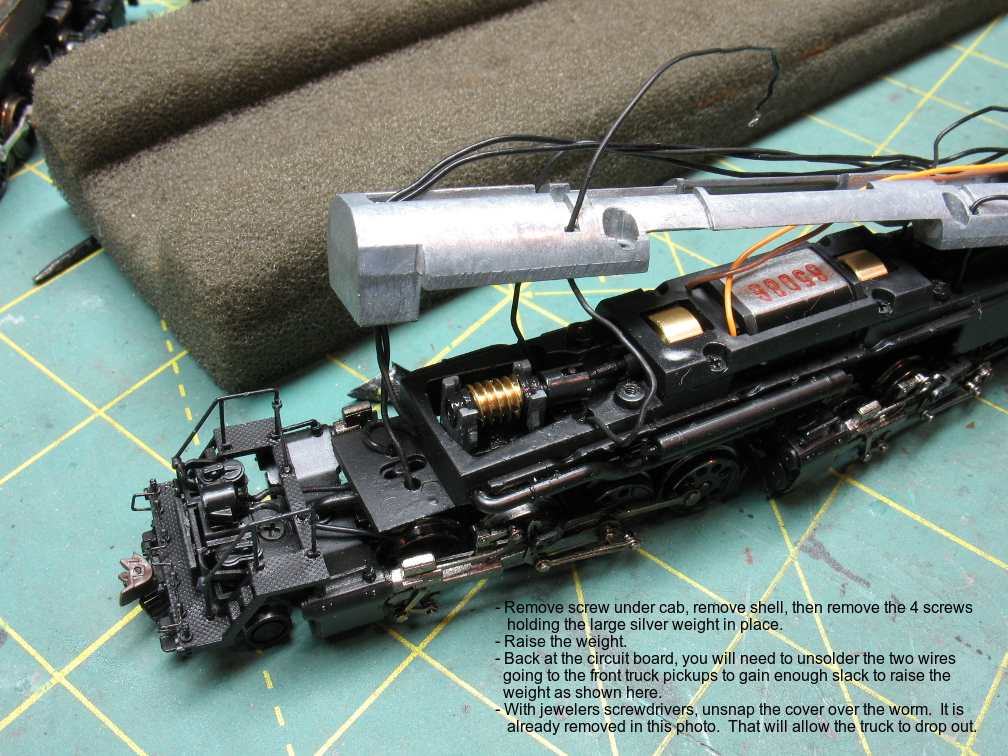

To repair this, you must disassemble the engine enough to drop the truck out of the frame.

Here are some photos:

The toughest part was getting the cover over the worm to come off. It's in a very tough spot.

I was able to get jewelers screwdrivers gently shoved in along each side to spread the cover a little, and then

it popped off. The cover is the only thing holding the truck (and the worm, and the drive shaft) in place.

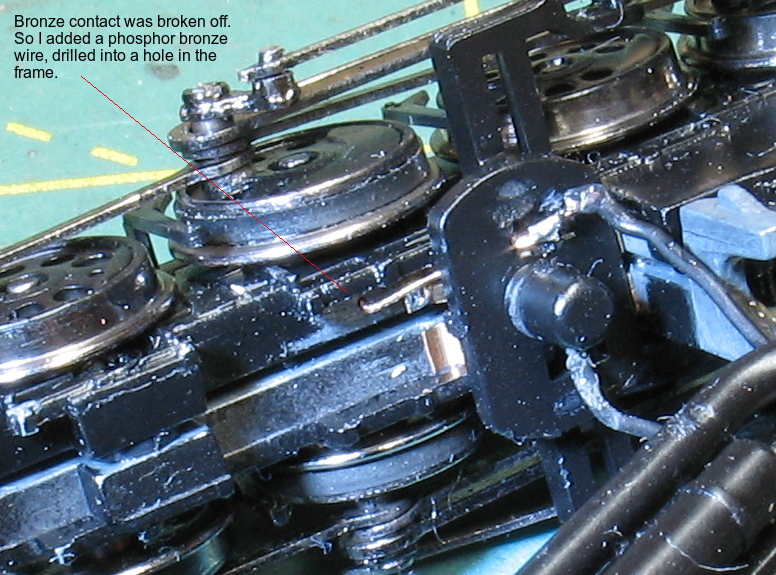

If you can, just resolder the wire to the little bronze tang sticking up near the center of the truck.

In my case, that was the failure point. The wire didn't break. The solder joint didn't break. The tang itself broke off.

What to do?

I drilled a diagonal hole in there, and shoved a bronze wire through. Then, I drilled a #80 hole directly into the frame, bent the wire,

and stuck the end of it into the hole. With lots of spring tension on it, I soldered the bronze wire to what was left of the original

contact. That keeps the wire in tight contact with the frame. Then, I soldered the pickup wire to the end of my

bronze wire. There is NOT much room between the top of the truck and the bottom of the frame, so you have to

allow just a little nub in there to solder to.

Here's a photo:

Finally, pull the wires up through the weight, and lower the weight back into place, being very careful not to let any wires

bunch up under the weight, or under the frame between the frame and the trucks. And be especially careful not to skin

any of the wires. Once you've got them all pulled up through and the weight is down, screw it back down and reroute

all the wires.

It runs beautifully once again. No more binding, hopping, or wobbling (which it was doing before I finally figured out what was

going on with that eccentric).