Sawmill Design/Build – Part 15--- Logging Car Pt. 2

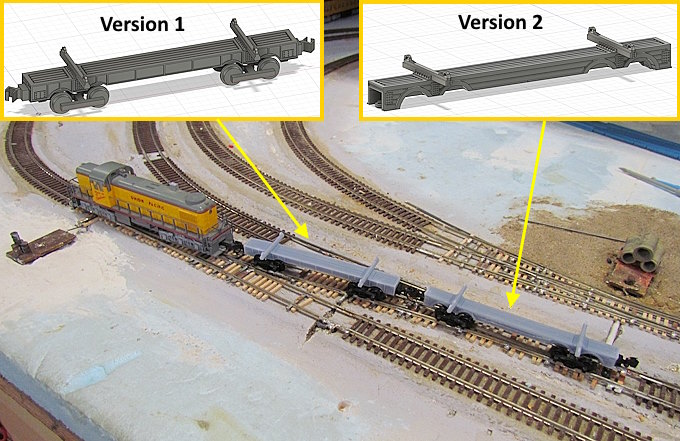

I put the two first versions of the log car on my small test layout and ran them around......

…........... pulling them and pushing them with no problems. Also pulled and pushed them through some of the turnouts without a problem. Not sure if all that will be true if there were 10 to 20 of them together. There is a little room for strips of lead weight in the bottoms at the moment which might help and with log loads things might prove to be better or not.

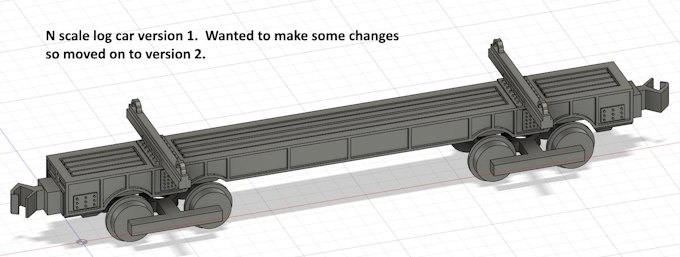

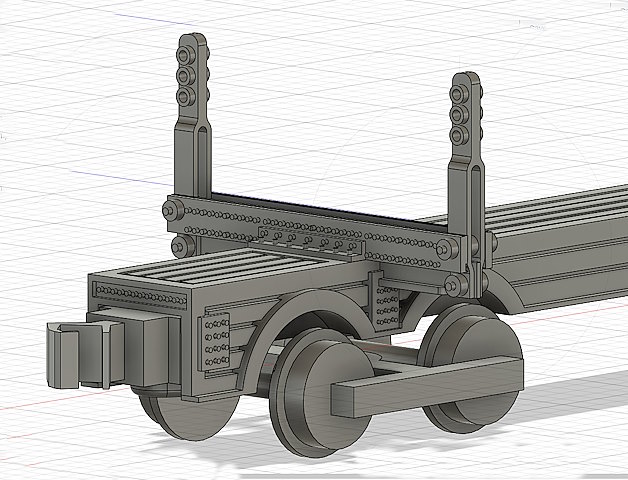

My first version of the car is above.

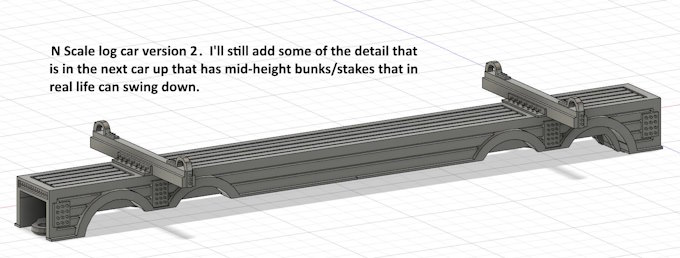

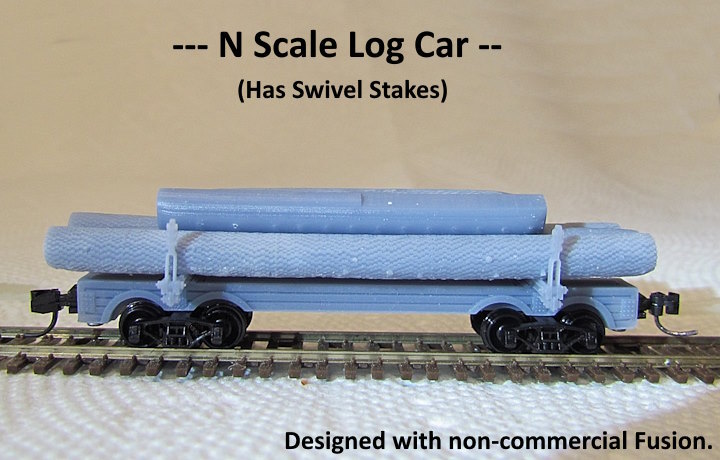

I changed the sides to look like above and will add some detail to the cross bunks as shown in the next image.

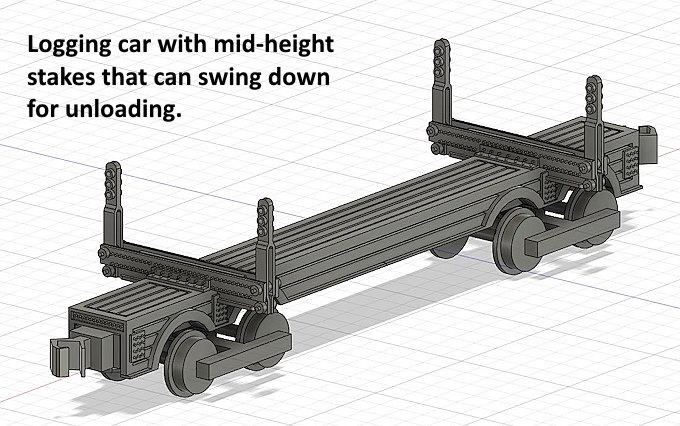

I hope to have three versions of the car. The one before the image above with the low bunks where chains would hold the logs on. Then the version above that has some mid-height side stakes to hold the logs. There are also three sets of holes in the tops of the stakes for chains that could further secure the logs.

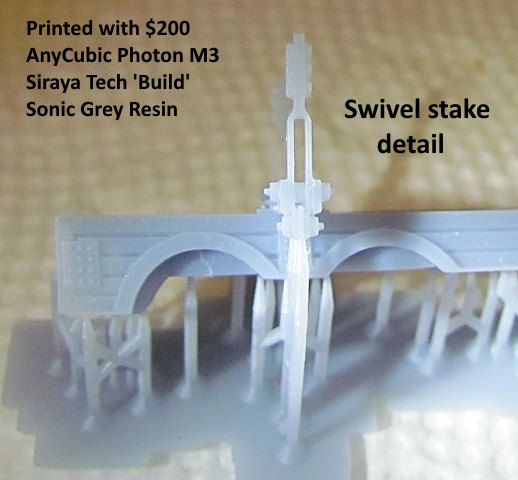

The stakes in real life as far as I can tell are designed to swing down. I wasn't able to find any real good pictures or descriptions of how that all works. From the pictures I saw there is a pivot point for the stake at the end of the bunk. Below that there is what I believe to be a pin that holds the stake up or pull it to rotate the stake down. Anyone have more info on that?

I'm happy with this car and after a few small mods will call it done.

The last car to be designed will look more like a flat car (extend the width of this car) with stake pockets on the side and 4 pairs of stakes that don't swing down. The car would be emptied a log at a time with mobile excavator looking piece of equipment or with a large forklift/ front-end loader piece of equipment like

a Wagner log loader which my sawmill will have along with

a large A frame hoist.

Above the car has been printed and still need to be removed from the supports which only takes a minute or so. The detail of the swivel stake is incredibly small, down to less than 2 N scale inches.

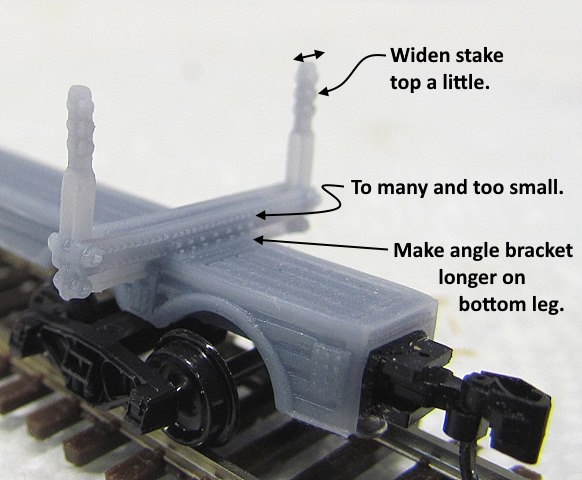

I have about an hours worth of changes I want to make to this car and then will move onto the last of the three versions.

A link to this whole build

( HERE ).

Sumner