So I've spent the last few days experimenting with how to print box car door and car sides and here's what I've learned.

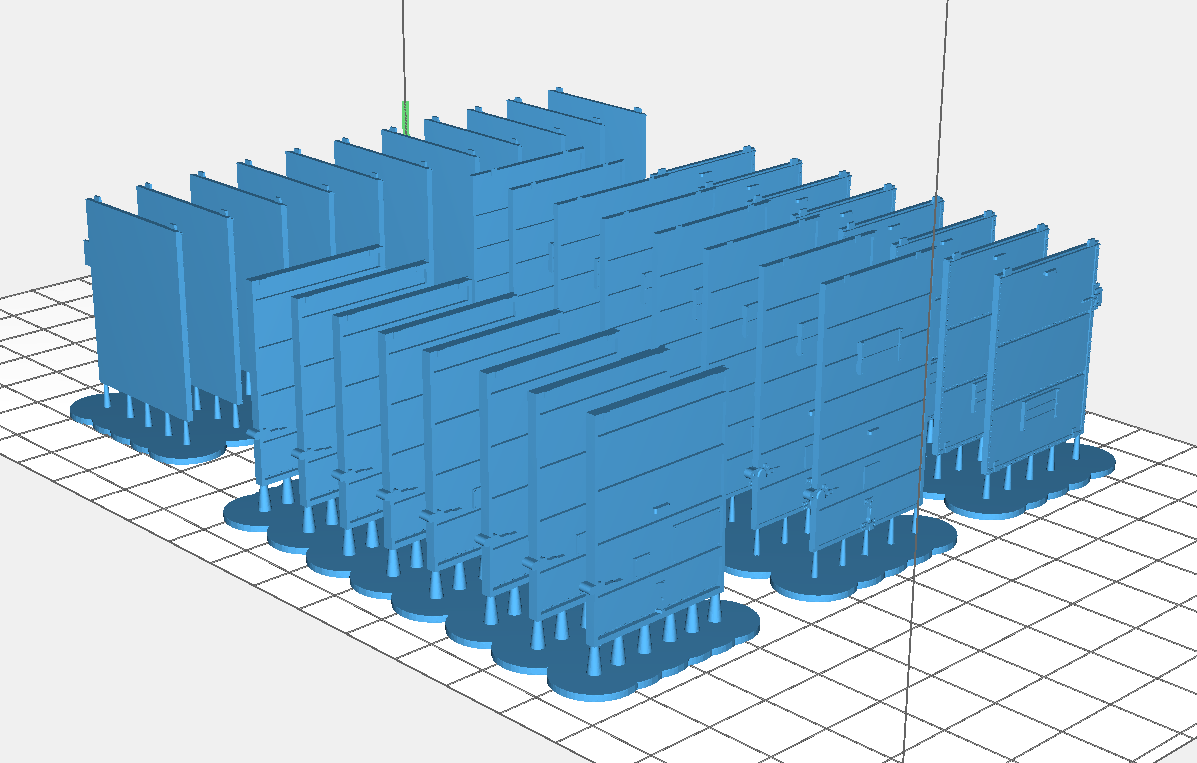

First of all, the ideal way to print these is standing straight up. It eliminates the build lines and you can fit a ton onto the platform. When Mark4Design printed some doors for me years ago, I notice they were just in a row without anything but bottom supports, so I tried this.

It worked okay with most of the thicker doors, but the thinnest one for my CMO Express box car, I had many failures. I think it's so thin it collapses on itself as it works up and down in the resin bath. Maybe I could tweak the print setting to fix this.

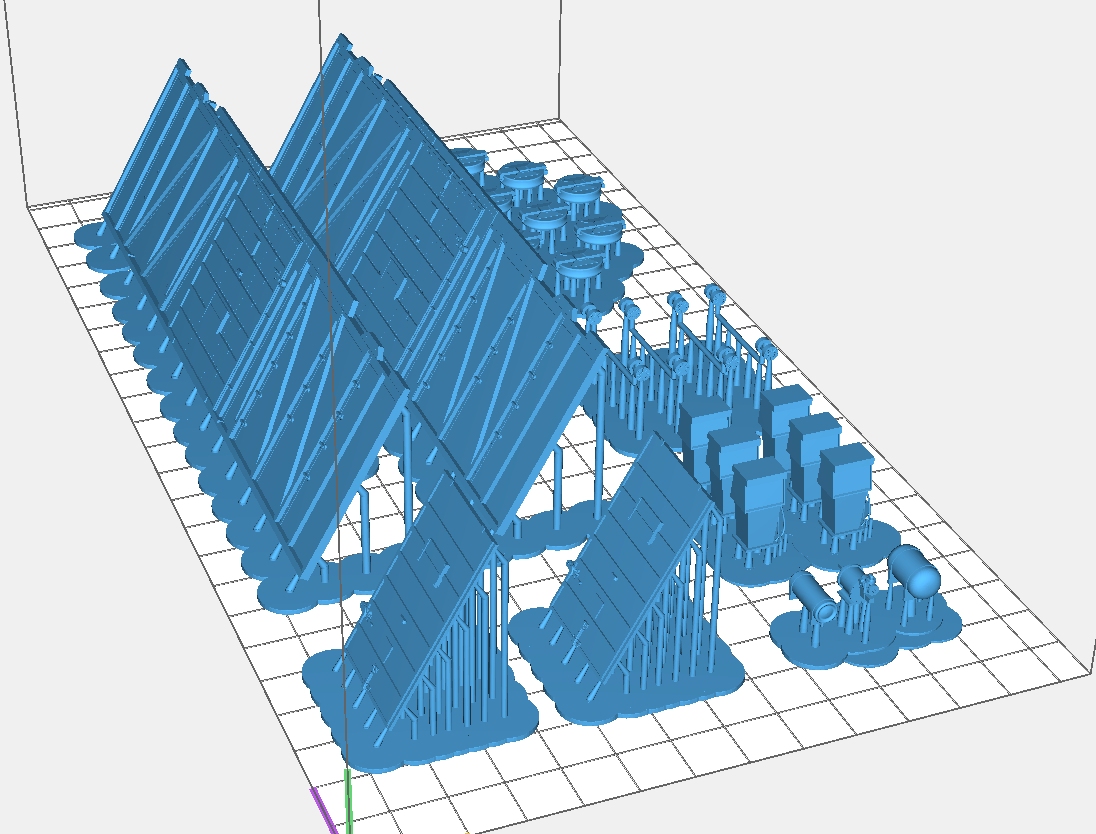

So the second attempt put the doors at an angle.

This worked but leaves build lines and had some warp when it cured.

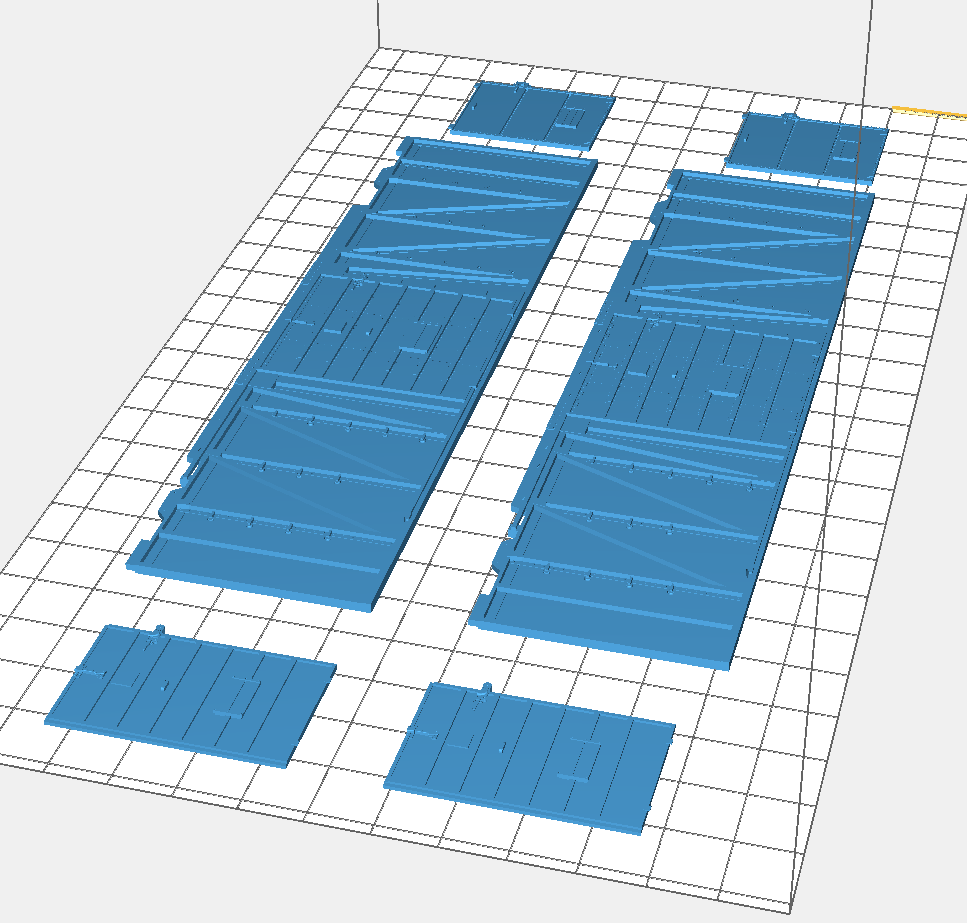

Third run put everything right on the plate without supports. Why not.

This added thickness to the parts at the FEP film.

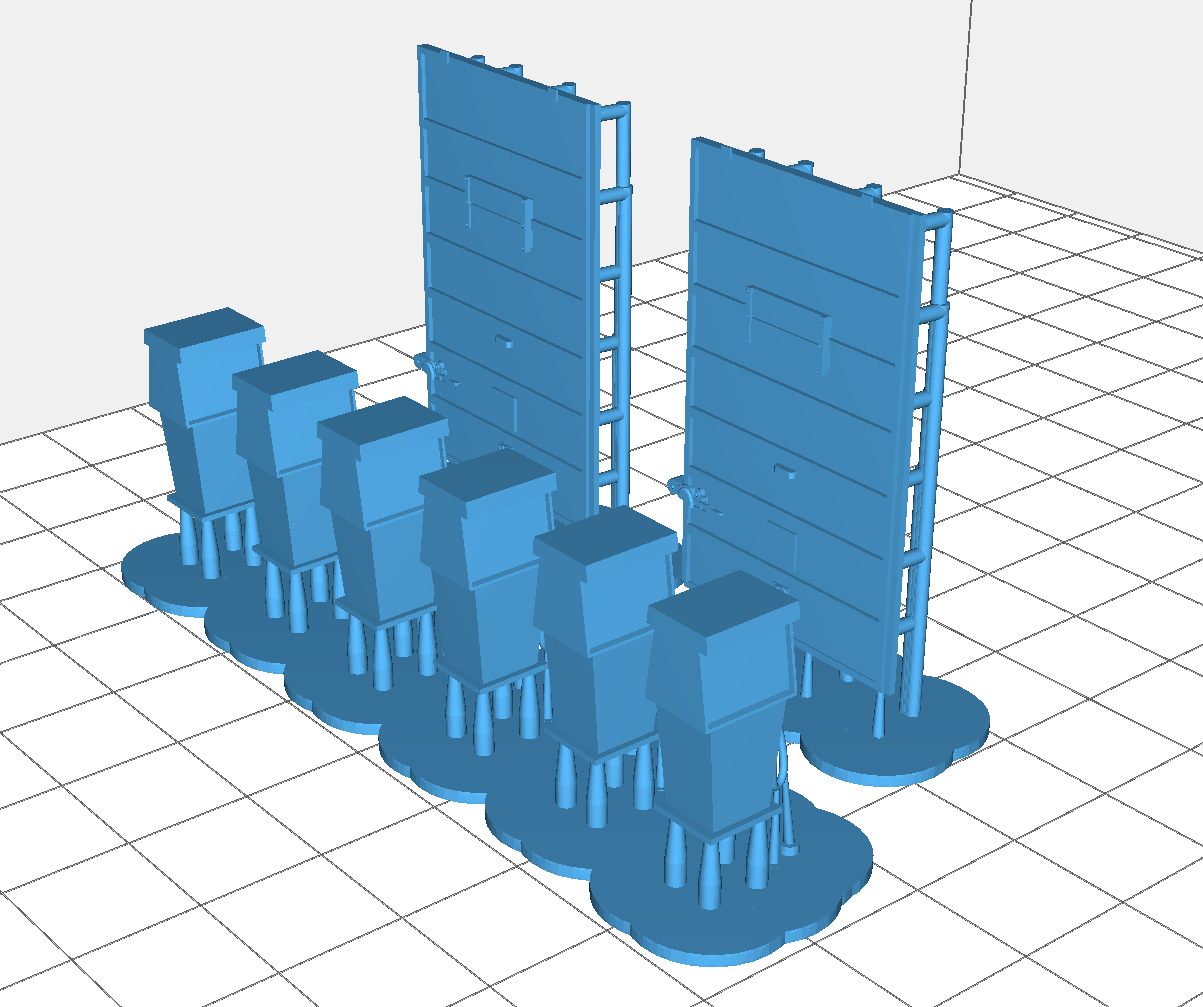

Forth try I went with supports.

This was a total failure and a lesson into why some parts have to print at an angle. Basically it prints the circle bases and then the supports, but once it gets to the flat part of the doors, it becomes a stronger bond to the platform than the supports are to the door and it rips off. Had to clean the FEP after this one.

My last attempt is getting some extra curing as I type. Will report later.

Jason