Well, I'm back after 3 weeks of work out of town and 2 weeks vacation.

And when I got home today, I had two packages of motors from Asia waiting on me.

And while 2 orders from overseas took a while.... man, I think I have finally hit on success.

Just a reminder......

My goal was to get a motor with a longer shaft so that I could place the worm on the motor shaft and keep the truck gear tower more or less in tact.

Here they are. The photos ended up being a little deceptive (but in a good way!). Remember, they only cost about a buck each.

Here is the first. Mitsumi R14. It has a 10mm long shaft. I didn't think that would be long enough and have the truck parts be stock, but if some of the plastic of the worm cover were trimmed, these would work. The body is the same overall dimensions as the Kato 11-105 motor-- just a bit longer.

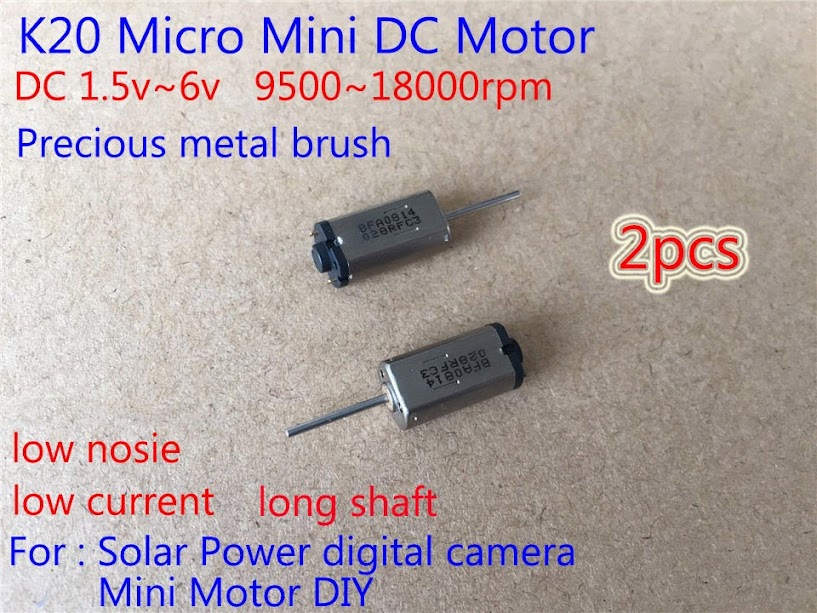

And here is the other. a K20 motor with a slightly longer shaft.

And THIS is the one where the photo is deceptive.

As you can see below, these two photos show motors that are about the same size.

But they are NOT the same size. The K20 motor is MUCH smaller. Also, where the other two motors have aluminium cases, this one feels like steel.

Here are all three to compare.

Kato critter motor on left.

Mitsumi R14 in middle

and K20 on right. The K20 is not as tall.

And, it is not as wide. It is thinner. And THAT is a plus!

I did not even try the R14 motor with the shorter shaft (requiring worm cover to be trimmed) and went straight for the K20.

I took the worm off the Kato critter motor. I then reamed it out as was suggested. I used a #61 Mascot drill bit. A #60 might have been better. But using the 61, I was able to get the worm to press fit onto the shaft without adhesive (that will come later).

I placed the worm and bearings at the very end of the shaft.

That left me JUST enough room to keep the worm cover as-is! Yay!

I carefully assembled everything and wired it up. It did run, but of course was noisy since the motor is not othetwise secure and spins and vibrates.

Now we get to the amazing part. The motor is the SAME width as the geartower!

So I just quickly got some styrene strip and superglued it to the motor and the geartower.

And it is now running on my layout beautifully.

Nice and smooth and quiet.

Remember, this is a 6 volt motor. So.....

Top power supply voltage (12 vt) could burn it out.

And even those 10 volt square wave pulses were in danger of heating up the motor.

But while on vacation, I found an old MRC Tech II Railmaster 2400 for 8 bucks.

I had been wanting one of these since you can turn pulses OFF.

So running on no pulses, at 20-25% throttle, this TP56 chassis now runs wonderfully.

And the motor is cool.