Hello Group,

Just wanted to add a link to a “very” detailed discussion on blueprinting slot car motors as it includes information on balancing the armature (which was discussed earlier in this thread).

http://slotblog.net/topic/51489-blueprinting-slot-car-motors/

Thanks, Mark

MarkJ, this is a great link. Prodigious in it's amount of information of what goes on inside miniature electric motors. I certainly learned a lot, there's incredible amount of information on "what is possible", from reading that link.

Appreciate your sharing the link and the cross-hobby, other-discipline perspective - Truly Amazing info which if you hadn't shared it, most of us would never have known existed. Thx.

------------

While I know we in model railroading are certainly am not trying to win any high speed model train contests (at least that's a niche of model railroading I've never encountered) short of:

.... or Kato Shinkansen .................

-------------------------

Let me be completely clear..... when we can buy good-running Atlas/Kato/Intermountain 5 pole skew wound motors right of out of the parts bin for $25.....

I suspect for most of us there's probably no need to tear down a readily available off-the-shelf motor.

More useful is the fact that we have clearly seen in this thread, that motor or the drivetrain alignment may not be the cause of a given noise problem - it may be the worm bearings / gear towers.

---------------------------

That having been said, from an academic and engineering perspective,

I noted

fascinating scientific comments in the

following.

==========================

Warning:

Begin Science Alert

==========================

------------------------------------------------------------------------------------------------------------------------------

From the thread's author:

------------------------------------------------------------------------------------------------------------------------------

As complete and deep a dissertation on (miniature electric) slot car motors as has ever been seen IMO. 83 images, in MS Word, it is 59 pages long!

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

From the primary author Ken Irwin, who happens to be from South Africa, just like Andre Kritzinger referenced in post reply #101 above in this thread:

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Warning: this article goes from simple to very complicated and possibly even to outrageous.Blueprinting means getting the (slot car racing) motor to “blueprint” or design condition (and in many cases better).

These motors are mass produced and suffer from a number of “problems” that can be improved upon.

Note: Check your local/national class rules before modifying a motor. There is no point in winning by cheating – or finding yourself disqualified after winning. Scrutineering tends to get more intense the more you win.

The principal problems (in order of importance/likelihood):

1) Poor alignments of armature to the motor’s magnetic field (the armature is hard up against one end or the other).

2) Loose magnets.

3) Loose bearing bushes.

4) Poor brush alignment.

5) Imperfectly balanced armature.

6) Improperly made armature – no lashing to secure wires.

7) Commutator out of true.

8 ) Brush spring set-up.

9) “Cheap” brushes and springs.

10) Relatively “soft” motor shafts – which can bend in a crash.

----------------------------------------------------

From hjames in the comments

----------------------------------------------------

This info is too good.

Took some of us decades to amass this info. Kind of like the magician that has the mask and gives up a lot of secrets but not all of them. Kudos to Ken Irwin's efforts and sharing it with us.

---------------------------------------------------------------------------------------------------------------------------------------------------------

JSing: Some teasers from referenced thread to whet your appetite, answering my "science" and "scientific instrument" premise of our thread

Below see a picture of a balanced armature from that thread:http://slotblog.net/topic/51489-blueprinting-slot-car-motors/ ---------------------------------------------------------------------------------------------------------------------------------------------------------

Step 6 – Set up your Armature

This is your armature.

We are going to do the following – in this order:

1) Set the spacing (as per above).

2) Check/set the “timing”.

3) Solder the commutator.

4) Add binding (if absent).

5) Replace shaft (if badly bent and worth the effort).

6) Balance the armature.

7) Skim the commutator.

------------------------------------------------------

Step 11 (How they)

Balance the armature:------------------------------------------------------

Step 11 – Balancing the Armature

Static vs Dynamic Balance If you simply add or remove weight from an out of balance object until it shows no tendency to rotate, this is termed “static balance”. It is obvious that you have probably not added or removed the weight from exactly opposite the error so when the motor is rotated at high speed it would still be out of balance to some extent.

“Dynamic balance” is accomplished by rotating the object at speed and analysing (on a sophisticated machine) the amount and location of the errors so they can be corrected for the object in motion.

It follows that a dynamically balanced object is also statically balanced (but not vice versa).

These motors are dynamically balanced but since this is a mass production process the balancing process is generally imperfect.

Dynamic balancing is way beyond anything you can do at home. (Having said that the web holds many plans for home built rigs so it is possible.)

So we go for a static balance on the understanding that if it is not statically balanced then neither is it correctly dynamically balanced and any improvement we make statically must still be better than leaving it as it was.

Balance on Stanley Knife blades is done like this:

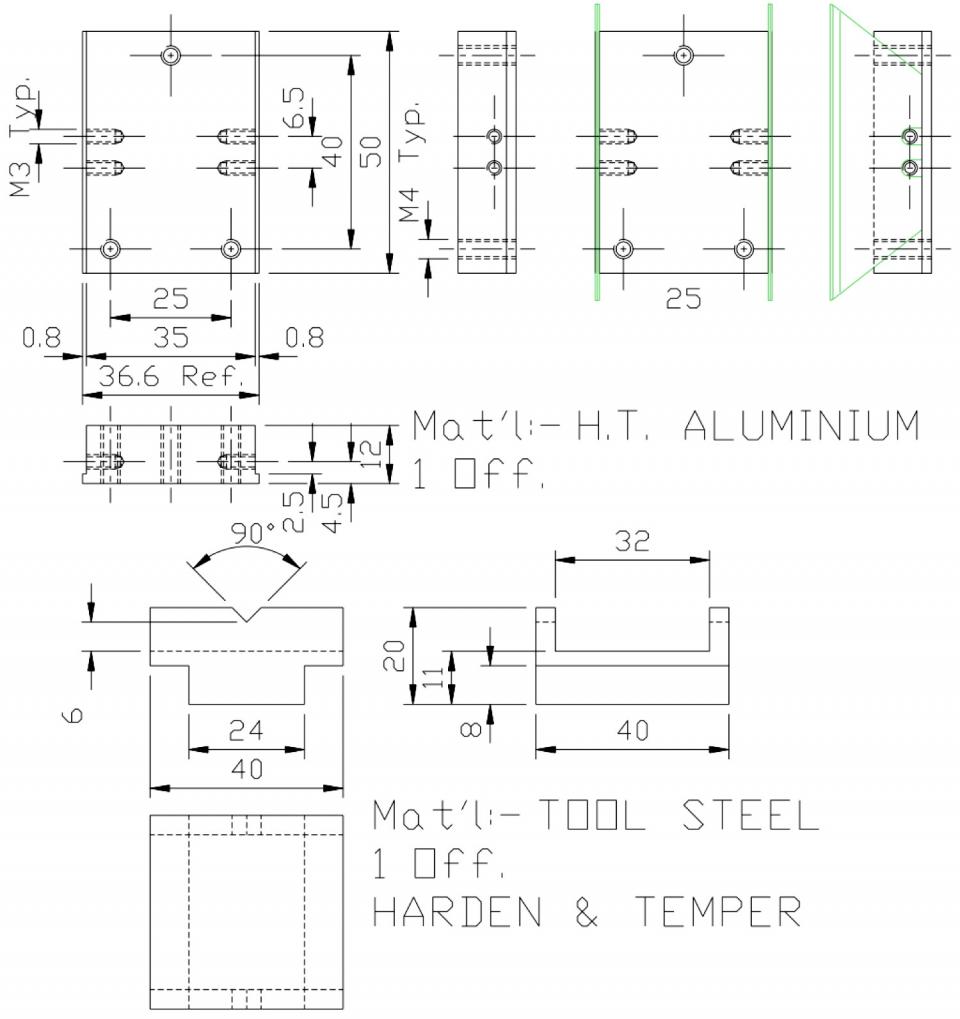

You can make the (balancing) block from dense fiberboard (see drawing below). The three levelling screws are used to eliminate any slope or bias.

Use brand new blades and be careful not to drop the armature onto them – place it very carefully in place – otherwise you create dents in the sharp edges which become obvious as biased behaviour).

Get it levelled so the armature does not roll to one end or the other by itself.

Allow the armature to roll (push it) slightly – if it has a heavy side it will always stop in the same position. Rotate multiple times to be sure.

If you can positively identify a heavy side – remove from the blades and drill material out of the heavy side.

Note: if it stops with one pole facing up and two down you must drill both “heavies”.

Use a 3mm drill – if there are two holes in that pole remove material equally from both. Don’t go too deep (max 0.5mm parallel portion depth). If you need to remove more, drill a third hole in between the existing two. If you drill too deep the core may break out at high revs.

Remove material in very small quantities, checking frequently. Repeat until the armature comes to rest in any position.

You can further “fine tune” balance by adding weight – just add a dab of lacquer to the “light” side windings – and repeat until balanced.

---------------------------------------------------------------------------------------

JSing: Here's

diagram for building a balancing block from dense fiberboard (see drawing below). The three levelling screws are used to eliminate any slope or bias.

---------------------------------------------------------------------------------------

------------------------------------------------

JSing: For what it's worth, this slot car racing thread helped me understand the practical application what this 1 hour YouTube on the engineering of "balancing of rotating masses" is trying to say:

This thread has brought to light a large amount of empirical practical experience... and with that, the theoretical science like above YouTube finally starts to make sense what they are talking about.

Whew!

==========================

END of Science Alert

==========================

JSing: It's fair to say, that I started this thread over the frustration of researching yet not finding the "practical science" nor the "real fundamental theories" behind tuning N scale model railroad locomotive mechanisms.

That is no longer the case.

Some serious science is possible, more than I humbly will ever need.

But it's better to know and bookmark:

http://slotblog.net/topic/51489-blueprinting-slot-car-motors/Than to be completely in the dark. We never know when awareness of this might someday come in handy.

=========================

Eh...... ok, what's next?