I know I havn't posted much but I swear I'm hard at work. Counting rivets. Soooooo many rivets.

You can imagine my excitement when Fredrick told me he had the tender underframes. For me that means it's time to get away from rivets for a bit, and design the speaker system. To best do that I need to do some real world testing. I come from a car audio back ground, (now I build home theatres and whole house audio systems as a part time gig). In my car audio days I built many a subwoofer enclosure. Fortunately we had published specifications, called Thielle/Small parameters which we could feed into a computer to spit out the optimum enclosure volume. Unfortunately these specs aren't published for our little speakers (not that I can find anyway) and the software used to calculate speaker enclosure volumes doesn't accept values as small as we are dealing with. This leaves us with trial and error.

We can, however, benefit from the subwoofers of days gone by as the theory scales down to enclosures of any size. Below are some givens that we can use to help design the system. There are volumes of books on this subject, and knowledge far more vast than mine, and what I'm including here is just a bit of basic theory:

Theory stuff:

An enclosure is a must. A speaker produces a wave off of the front surface of the woofer, however it also produces one off of the back surface. They are 180 degrees out of phase with each other. If the two are allowed meet they cancel each other out and you get no bass. An enclosure prevents this. We've seen evidence of this recently in the locos that

@jdcolombo has built. All have sealed enclosures and all sound amazing.

The larger the enclosure (and the speaker) the lower the frequency response (usually).

Sealed enclosures create flatter response and are considered more "musical" and natural sounding. They are also the easiest to design and build.

For a given set of woofer specs the sealed enclosure will be one of the smallest you can build.

Ported enclosures are usually louder over all, and have deeper bass extension due to the port being tuned to a lower frequency which boosts the volume at the bottom end of its frequency response.

Ported enclosures are also quite a bit larger than their sealed counter parts.

Adding another enclosure on the front of the speaker, in addition to the enclosure on the back, and porting them both tuned to different frequencies creates an even louder enclosure that produces loads of bass. It also blocks a lot of the high frequencies as they get trapped inside the enclosure and absorbed by it. This design is called a band pass enclosure.

Low frequencies are not directional. They radiate out in all directions which is why a lose woofer gets alot of its sound canceled out by its own rear wave. Higher frequencies don't do this. They are very directional. With our trains we're actually not really dealing with bass. Our little speakers only extend down to about 300hz which is more the mid-bass, or low mid-range area of the spectrum. Still low enough to need an enclosure though.

Every speaker system should have a cross-over network. A cross over filters out frequencies that are beyond the range a speaker can play. In a worst case scenario, left unfiltered, these frequencies can damage speakers. Removing them reduces distortion and directs the power only to frequencies that the speaker can actually play, increasing efficiency as well as sound quality. This is most important with lower frequencies as they cause the most distortion and do the most damage.

Boring theory complete.

Design Considerations:

When we are dealing with model trains, especially N scale, we don't really have the luxury of fine tuning the speaker enclosures as we're usually just trying to fit in what ever we can, if there is even room for an enclosure at all. The Royal Hudson has quite a lot of space in the tender. Not having the ability to design an enclosure on spec, I decided to use the bigger is better method. I calculated the space needed to run wires, and allow room for the structure of the tender, and came up with an enclosure that used up much of the rest of the available space between the trucks.

We ordered multiples of the tender frames so I could build multiple examples and do proper side by side comparisons of each installation to see what sounds the best.

I have five test subjects. All will use a sealed enclosure design.

Test case 1:

Zimo Sugar Cube in the matching enclosure. Woofer firing through the floor.

Test Case 2:

Zimo Sugar Cube in the maching enclosure. Playing into the tender cavity, with sound escaping through the holes where the electrical pick ups come through the floor.

Test case 3:

Knowles/Fox in a custom built enclosure. Woofer firing through the floor.

Test Case 4:

Knowles/Fox in a custom built enclosure. Playing into the tender cavity, with sound escaping through the holes where the electrical pick ups come through the floor.

Test case 5:

ESU oval speaker in a custom made enclosure. Woofer firing through the floor. This is the largest of the speakers in this test and is too large to fit any other way.

I hear a lot of people saying that they feel the speakers sound better when they are played into the locomotive vs having the speaker play out unobstructed, like through a fuel tank for example. What I think is happening here is that the loco shell is acting a bit like the band pass enclosure I described above. Our little speakers are really heavy in the high end of the sound frequency spectrum. Trapping the sound inside the loco blocks a lot of these highs, reducing their volume so your brain hears a sound that's more in balance with the weaker bottom end. We hear this as better sound with more bass. This is why I've included this style of installation in my tests.

Equipment I'll use for the tests:

Test Tones: I have test tones on my computer that play specific frequencies that I can choose.

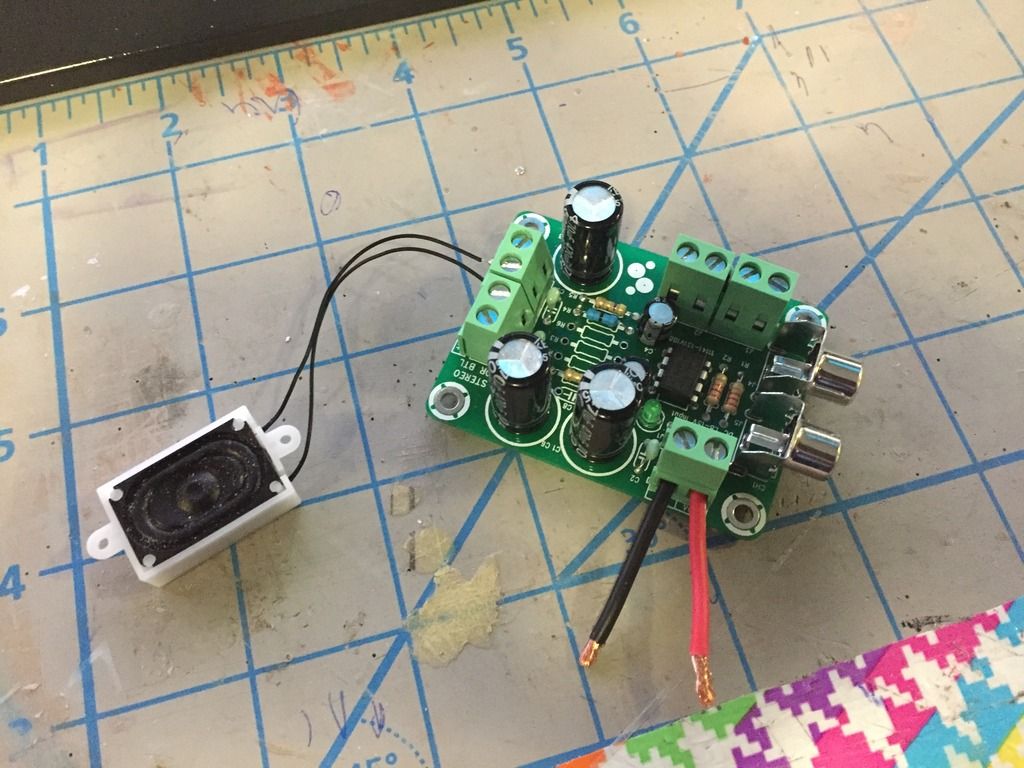

Amplifier: I bought a 1 watt headphone amplifier kit on line which can produce roughly the same amount of power as the ESU decoders we plan to use.

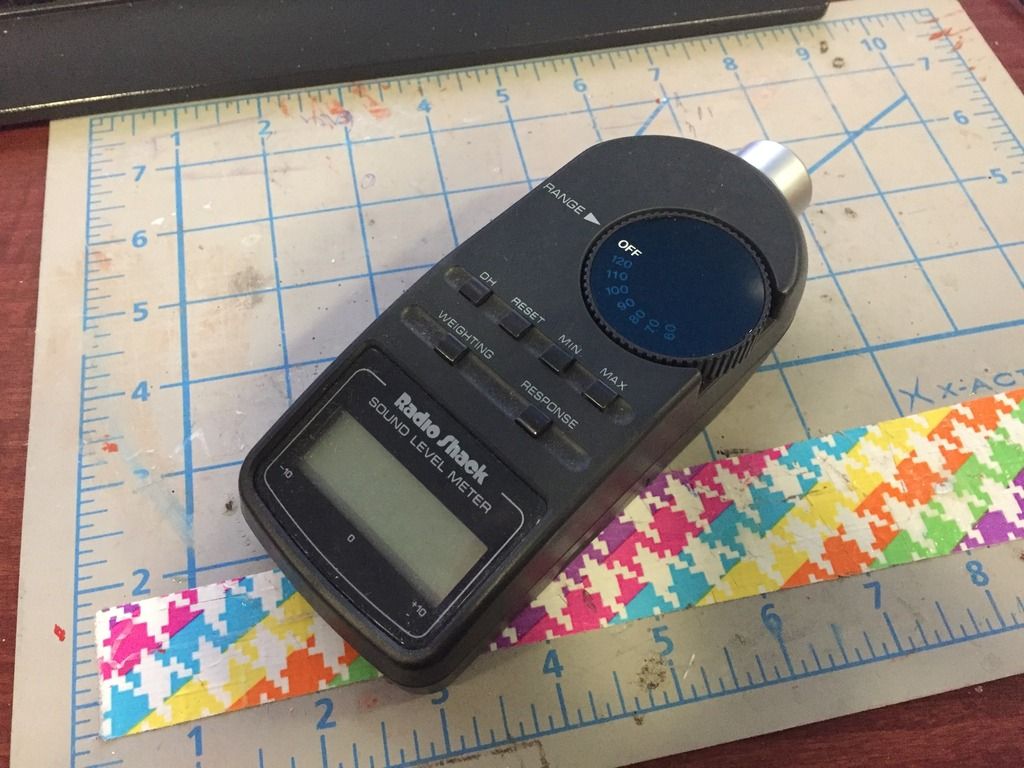

Sound Pressure Level (SPL) meter. This will be placed a specified distance from each speaker installation and measure the volume of the test tones in decibels (dB).

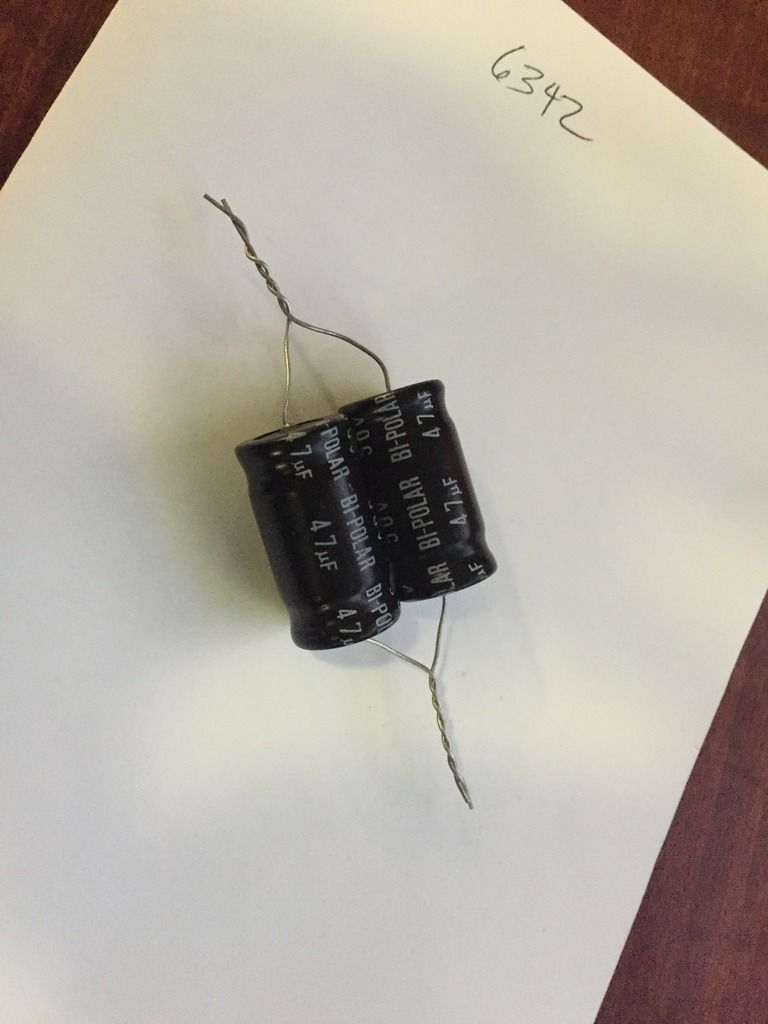

Bipolar Capacitors: here we have two 47uF caps wired in parallel which adds up to 94uF. 94uF of capacitance creates a cross over that will filter out any low frequencies below 204.9 Hz, at 6dB per octave. This means they cut out all of the distortion causing energy that you'll never hear anyway as the speakers can't produce it. They have to be bipolar caps because in its electrical form, sound is A/C. These 50v caps are obviously way too big to fit in a loco but if they are found to improve the quality of sound and reduce audible distortion I can work on finding smaller package sizes. A quick look found some on eBay in a 16 volt, 6.3mm x 11mm package which we could fit in the tender. Unless 16v would explode....

@peteski ?

How I plan to do my tests:

The speakers will be installled in identical enclosures (with the exception of the Zimo) and whether they need the the exterior shell to direct the sound or not, it will be installed on each mock up for the purpose of uniformity.

Each tender mock up will be placed in the exact same location, in relation to the SPL meter, and subjected to the same test tones at the same volume level. They'll also all be on trucks and track since this affects how the sound is reflected off of the surface under the tender. By doing this I can measure the volume of each test tone and create a graph of the frequency response of each installation. The idea is not to find the one that is the loudest, but the one that has the flattest response and most importantly, the lowest frequency response.

Finally, I'll connect each one up to a LokSound decoder so we can switch between each and decide with an actual steam sound file which sounds the best. We can do lab tests until the cows come home but ultimately what matters is what we think actually sounds the best with steam sounds.

Once testing is complete, Fredrick can incorporate that enclosure into the frame design.

Up next, test results.

Craig.