I've noticed various comments here about certain Atlas code 55 turnouts being troublesome, others maybe being better, and so on.

I'm designing a layout now, and like the look of Atlas code 55. As I finish up the design, I realize that in some places I have choices of which turnout I can use.

In general, my design rule is to use the largest frog I can - #10 where there's room, #5 only in freight yard or sidings, #7 where #10 won't fit. Curved turnouts where they are needed to make the track flow nicely.

But - I've got a spot (on the main) where I could use either a #7 or a curved turnout. I can't fit a #10. - which would you choose and why?

George

I know that some folks prefer Peco, Micro-Engineering, Kato, etc., or even making their own, all for various good reasons. For this design I'm going with Atlas 55 as much as I can.

Although using the largest frog on your turnouts is a good idea, the effective diverging radius between the frog and the closure point heels is what makes your trains flow through...with larger frogs demanding larger effective diverging radii.

HOWEVER...and this is important...Atlas 55 turnouts are much shorter between the frog and the closure point heels than they would be if they were proportioned prototypically. For example, their #5 turnouts have an effective diverging radius of what a normally proportioned #4 has, and their #7 has virtually the same diverging radius of what a normally proportioned #6 has, and their #10 has the same problem.

So, the hard fact is that Micro Engineering #6's are properly proportioned, and oddly-proportioned Atlas 55 #7's only offer a tiny advantage in effective diverging radius over ME #6's

Micro Engineering #6's look better than Atlas 55 #7's in several ways, which include being properly proportioned, having actual nickel-silver guard rails, frogs and closure points (as opposed to Atlas' brightly plated "mystery-metal" parts). ME #6's also have an over-center spring mechanism at the throwbar which means you can just flick the points and they'll stay in place as opposed to Atlas 55 turnouts which need some kind of switching mechanism to work properly.

Also, ME #6's frogs are short enough that when properly gapped, work just fine as a dead frog, and my LL switchers run smoothly over the two I have on my Echo Yard layout section.

Additionally, ME #6's are slightly shorter than Atlas 55 #7's so they'll fit better in tight situations.

Atlas 55#10's, even though they are too short to be actual #10's with the equivalent larger effective diverging radius, still look pretty good and work well too, and probably have the equivalent diverging radius of a #9.

Since Atlas curved turnouts list both large and small radii, you at least know what those radii are, as opposed to their #5's, #7's and #10's. Using curved turnouts will often work better in the space available than "straight" turnouts, so...my recommendation is for the Atlas 55 curved turnout...NOT the badly proportioned #7. On the other hand, maybe a ME #6 might work???

You should know that Atlas 55 turnouts have some problems with their electrical connections coming loose after a while. There are several solutions to that problem which require soldering jumpers and feeders to the turnouts before you lay them. I don't have the links right now, but I am sure others will provide them if you ask.

Truthfully, after cutting away the plastic and soldering in the preventative jumpers and feeders, it would only take a few minutes more to make your own, and not be limited ever again to what a manufacturer has decided you should/can use in designing your layout. Just sayin'....

If you happen to be designing your layout using a model railroading CAD program, make sure you use the included Atlas 55 turnout templates included with the program and not actual #7 & #10 templates, but check to make sure the proportions in the program reflect the mis-proportioning of Atlas turnouts, or you may end up with some unpleasant surprises when getting around to actually laying track.

I also recommend ME C55 flex over Atlas 55 flex because of the larger and less realistic looking nubs which hold the rails to the ties on the Atlas 55 track. If you have any cars or engines with older "pizza-cutter" flanges on the wheelsets, they will run smoothly on ME C55 track, but hit every nub on Atlas 55 track. Plus, I like being able to lay flex to an exact centerline, rather than have my track flop around like Atlas 55 flex does. ME C55 track also is more exactly gauged than Atlas with their one-loose-rail floppy philosophy, which means I can run more realistic, narrow FVM lo-pro metal wheelsets and not worry about them falling off the rails.

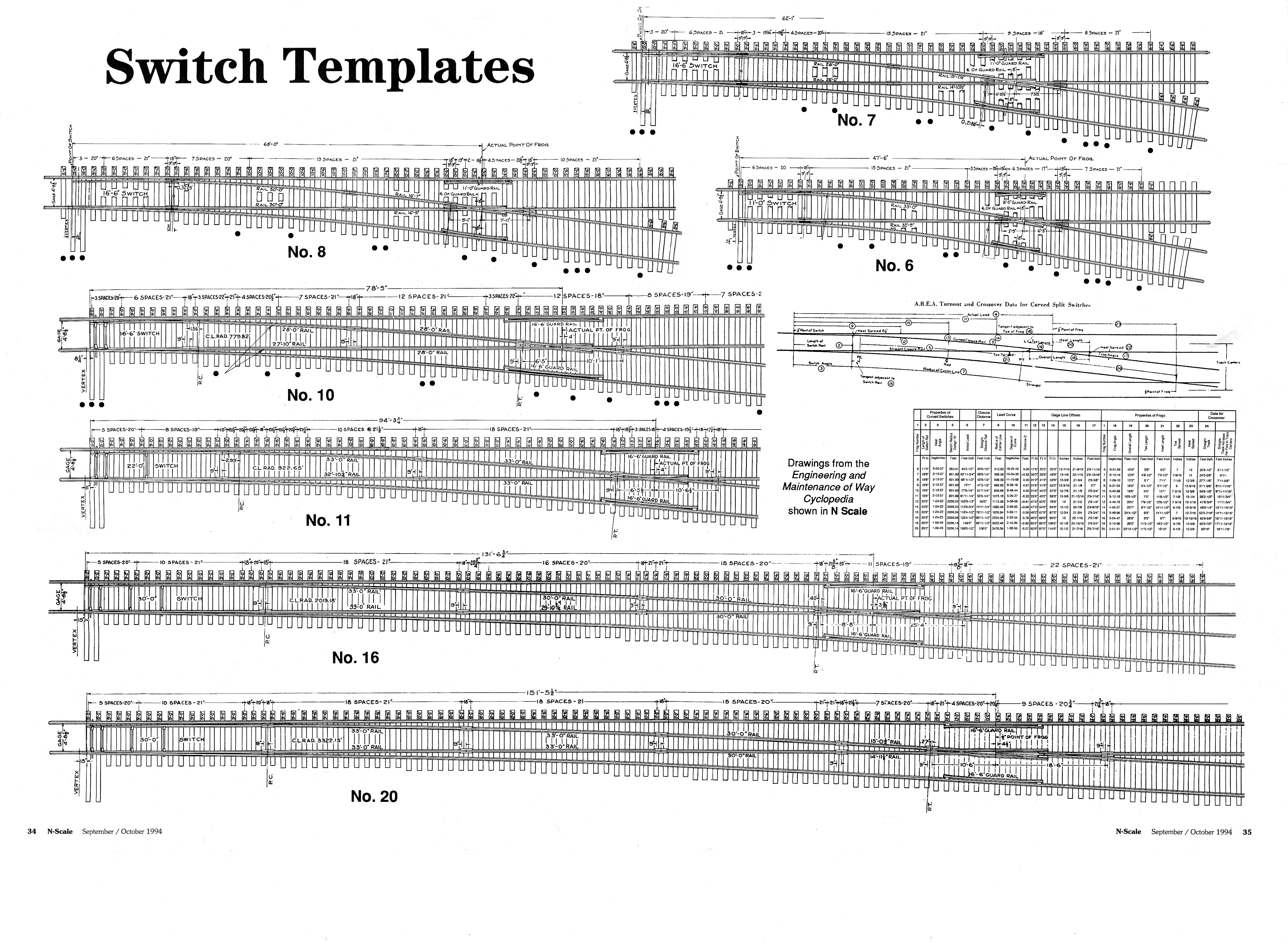

To illustrate my point about turnout proportions, here are a couple of photos...

Photo (1) - Atlas 55 #7 and ME C55 #6 side-by-side comparo...notice the Atlas #7 is only very slightly longer than the ME #6: Photo (2) - AAR Scale Drawings of Prototype Turnouts...notice how much longer a prototype #7 is than the #6:

Photo (2) - AAR Scale Drawings of Prototype Turnouts...notice how much longer a prototype #7 is than the #6:

I don't find any problem whatsoever with mixing brands according to your needs. Atlas & ME track products function together just fine, so using ME flex and Atlas turnouts along with ME turnouts will both look and function just fine too. Why not have both good looks and excellent functionality at the same time, eh? ....Just askin'

Cheerio!

Bob Gilmore