I thought some of you might be interested in another way of building steam locomotives. Strictly speaking, this isn't N scale, it's 2mm finescale. This was mentioned briefly in the European model thread.

The 2mm Association

http://www.2mm.org.uk/ provide etched replacement chassis to convert commercial N gauge models to 2mm. This is one of those and my first 2mm locomotive.

This is a Jinty 0-6-0 tank engine build by the LMS in the 1920s. I chose this because I had the body for it already and it is appropriate for my club's 2mm layout.

The standard method for 2mm is a split chassis meaning that both frames are live with an insulating material in between.

So the chassis arrives as an etch in nickel silver. I didn't think to take a picture. The first step is to solder the bearing into the etch. During this step the gearbox gets folded up and soldered as well.

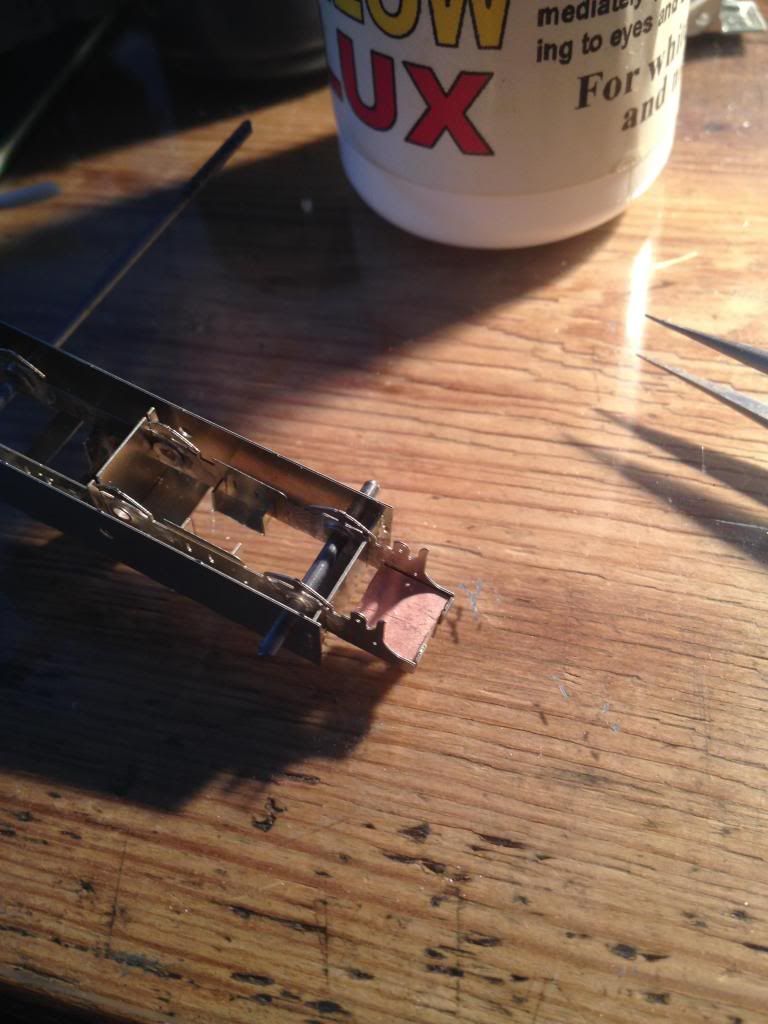

The insulation between the frames is copperclad pcb. This is easy to solder but can then be gaped to insulate the frames. Three pieces are needed, one at each end and one in the middle. There are tabs on the etch which mark the location of the pcb

Included on the etch was a helpful box which holds the frames at the right spacing and lines up the axles. Here the frames, pcb and temporary axle can be seen.

And the chassis once the two frames were joined together.

This is called 2mm finescale for a reason. Here is a driving wheel alongside a BLMA truck. The tread is similar but the flange is tiny.

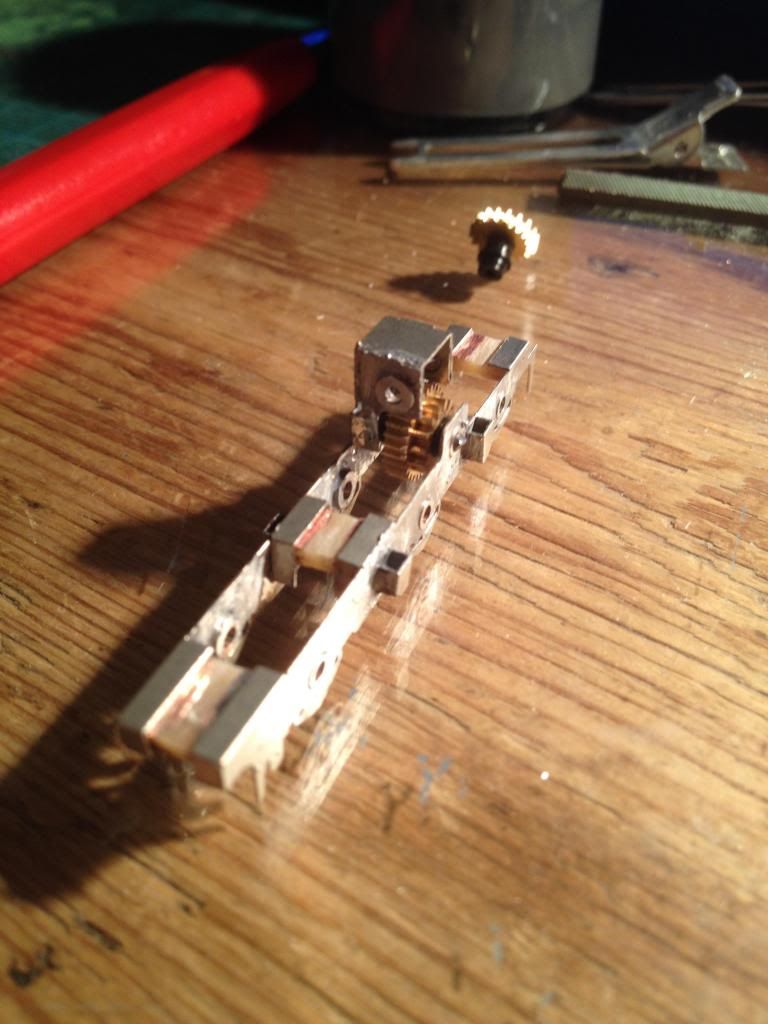

The gears are mounted on a sort of plastic tube called a muff. It is a tight fit for both the gear and the axle. Here are the two gear axles. The one with only one gear will carry the middle set of driving wheels.

Here is the chassis with a set of gears installed. The gaped pcb can be seen as well.

The connecting rods are quite cleverly designed. They start on the etch in 5 separate parts.

There are then two folds which form the rods and strengthen the bearings. This is all soldered together.

The non powered axles are pressed into plain muffs and the center powered axle is pressed into the muff with the single gear.

One of the center wheels isn't in gauge yet.

This hasn't taken very long to do. Maybe 8 hours? Possibly less. All of this has happened today. Tomorrow will consist of quartering, mounting the motor, painting, etc.