Had some free time today, so I began to experiment with Jax Blackener.

As I had thought, it is essentially Selenium Acid.

Here is the bottle in the middle. I poured a little on the right. And on the left is some dissolved baking soda to neutralize the acid.

I wanted to experiment before I did anything to my nice wheels. So I dug in my parts box and found some old wheels to some 1960s locos.

I cleaned them up with acetone and a toothbrush.

I then only used tweezers to pick them up.

Here was the first attempt.

Straight selenium acid right out of the bottle- I know others said dilute, but this was experimenting right?

No fizzing or bubbling or anything like that.

Took a good while 5 minutes or so before the acid worked on the nickel (or whatever it is).

Finally started turning black.

End result:

Splotchy (look at back wheel).

Had a black fuzzy covering that wiped off 85% (as you can see here- wiped off).

Here is the second one- of course it may have been made of different materials.

This one has a brass axle.

I diluted the acid ~50%.

WOW. This stuff is all over and attacks brass immediately. Turned VERY black.

Once again, the nickel chrome whatever took much longer.

This time I constantly swirled the acid in the fully covered wheelset.

Results were much more even and permanent.

This is after wiping- as before.

The blackened brass flaked.

Also, that is still a bit splotchy.

I want better results than this.

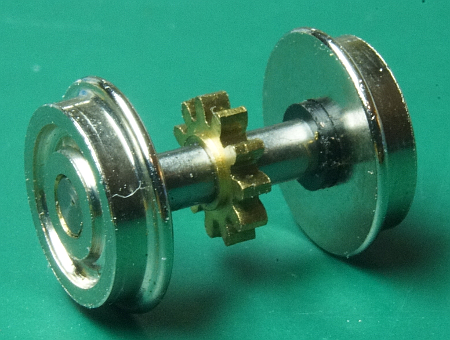

Here is my Kumata wheelset. It is very nice- but very shiny!

The first thing I see is a BRASS gear in the center.

Directions say you can brush on, but my best results before was in immersion and constant swirling.

That will mean that gear will be black and flaky making a lot of gunk in the drive train.

So I'm thinking about a couple of things.

First, I'm going to leave my Railroad Fair loco alone for now.

Since I also have the Ready To Run cigar EP-2, I decided to experiment on that.

In fact, that's what I have done in some of this project.

This was my test bed to try out ideas.

I debated whether to use my NWSL Puller to remove just the wheels (leaving the axles and gear alone).

But that is a LOT of work- and I still have to gently beat the wheels back on. I predict that process would damage the blackening- thus unproductive.

So maybe, I'll blacken the wheels and then run them in the RTR for a while to wear the blackening off the gears and THEN place them in the Railroad Fair loco.

So I pulled all of the wheels out of it. That's a lot of axle for one loco (14!).

Washed with Dawn and hot water with a toothbrush.

That's as far as I got...... but here is what I'm thinking (brainstorming time).

I think the problem with blackening is the VERY slick nickel surface.

I think when I get some free time this week, I may take a wheelset and use the Air Eraser on it (and I'll go easy).

That will place a rough surface on it.

Of course I'll focus on the outside surface and try to stay away from the tread, axle and gear.

In fact, I may make a jig (a brass or styrene plate with a perfect matching hole in it so the grit only goes on the outside surface).

With an etched surface, I would think the blackening would be darker and more permanent.

Ideas and comments welcome.