If this ends up being a duplicate or triplicate posting I apologize, I tried it once by attaching a copy of my drawing and got an error saying the upload folder was full. Tried it again without the attachment and it said I had already posted the message (I don't see it) Third try here...

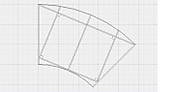

Anyway, I'm working on a sectional layout design and was wondering if anyone here had ever built a curved corner module. That is, with both the inside and outside module faces curved, as opposed to the nTrak method of a trapezoid shape, or having the inside straight, both of which are easier to frame. I have an idea of how to do it, but if anyone has a suggestion on framing it out, I would like to avoid reinventing the wheel.

Frame material would be 1/2" ply, with the curved pieces being 1/4" ply and the whole thing decked with 1/4" ply. The curve radii are very large: approx. 46" inside and 82" outside. I don't imagine bending 1/4" ply to that radius would be too hard. The three "x" joints near the outside curve in the drawing would be lapped.

Does anyone see any problems with this or have a better suggestion?

Pete