Rich,

For rivets that bulged out (like real ones) You have to half etch the whole piece leaving only the rivets un-etched. Those passenger car sides I made have rivets that are dimples. So only the rivet is half etched. If I put the rivet on both sides of the artwork in would become a hole instead of an indent.

The problem with half etching whole pieces at home is that I don't have a pressurized tank to keep the acid eating evenly. Plus I don't have jets spraying the etch to the sheets. I'm just dipping the sheet in a tub and agitating it a bit. So I get what you saw in the boxcab piece.

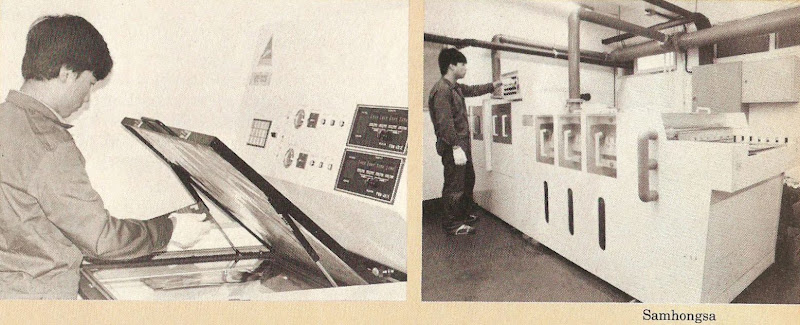

You can look at Bob's bridges and see that rivet detail is possible, but he has much more sophisticated equipment. Here is one brass MFG's etching equipment:

If you want "real" rivets I would get with a professional etcher and try doing the artwork yourself. If you can live with dimples then you can do that at home.