I had some small Nn3 (Z gauge) wheels that were insulated on both sides. They had wobbles, I was told they were not machine made so it is hard to get them all perfect. One Nn3 modeler said he would fix them for me with a jig me made on his lathe. So instead of sending them out I figured I could try to make the jig myself.

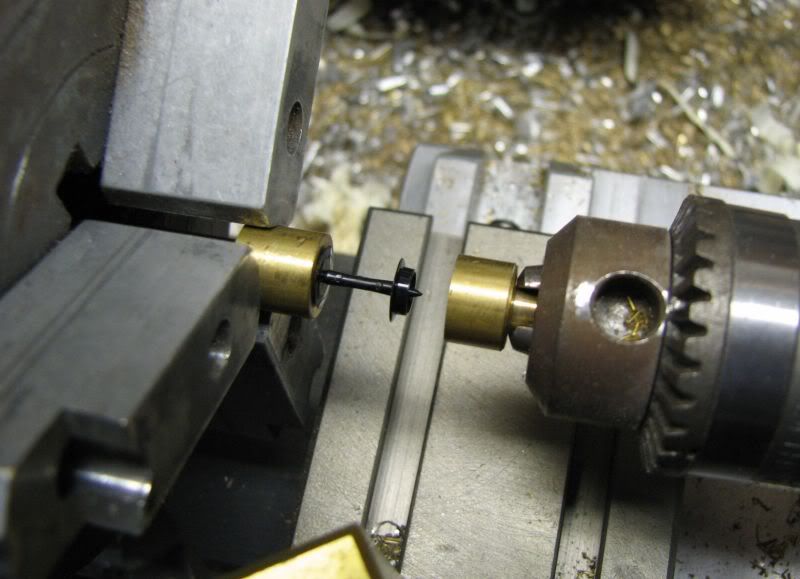

Just a mock up photo showing a plastic wheel set, but you get the idea. There are 2 brass "cups" that were turned to fit the wheels snug. Then I just press the axle in place with everything in a straight line. Out of 4 wheels, I was able to get 3 of them perfect this way.

Not sure if this really helps you, but might give you some ideas. Same idea might work in a drill or arbor press, but you would need to make sure the bottom cup is centered with the top. (The lathe does that on it's own)